UkuJika omnye

Xa uthatha ibhanti lokuhambisa kwintshukumo yokujika.Icandelo le-arc lokuhambisa liya kudibaniswa kunye nomqhubi othe tye kwaye iziphelo zombini zecandelo le-arc kufuneka zikhokelwe ngokuthe ngqo, kwaye emva koko umqhubi uya kusebenza kakuhle.

I-radius yangaphakathi ifuna ubuncinane amaxesha angama-2.2 ububanzi bebhanti yokuhambisa.

I-STL1 ≧ 1.5 XW okanye i-STL1 ≧ 1000mm

Ukujika okukodwa akupheleli kwi-90 °;kufuneka ithobele umda wokujika i-radius kwaye wenze uyilo ukusuka kwi-15 °, 30 °, 45 °, 60 °, 75 °, 90 °, .... ukuya kwi-360 °.

Ukujika kothotho

Xa uthatha ibhanti lokuhambisa kwintshukumo yokujika.Icandelo le-arc lokuhambisa liya kudibaniswa kunye nomqhubi othe tye kwaye iziphelo zombini zecandelo le-arc kufuneka zikhokelwe ngokuthe ngqo, kwaye emva koko umqhubi uya kusebenza kakuhle.Ubude bomsebenzi othe ngqo bufuna amaxesha angama-2 ububanzi bebhanti yokuhambisa.Kwisiriyali yokujika intshukumo , nceda musa ukuyila ngaphezulu kokujika kwe-4.

I-radius yangaphakathi ifuna ubuncinane amaxesha angama-2.2 ububanzi bebhanti yokuhambisa.

I-STL1 ≧ 1.5 XW okanye i-STL1 ≧ 1000mm

I-STL2 ≧ 2 XW okanye i-STL2 ≧ 1500mm

Amanqaku

Xa umqhubi wemoto esebenza, kuya kuba lula ukwenza ingxolo engaqhelekanga ngenxa yesenzeko sokunqumama kunye nokungcangcazela.Isiphelo esingenamsebenzi sebhanti asikwazanga ukushukuma de kubekho ukutsaleleka okwaneleyo ukoyisa ingxabano phakathi kwebhanti kunye nendlela yokuthwala.Le ngxolo inokupheliswa ngokuthatha igrisi okanye ulwelo lwesepha ukuthambisa iintsimbi kunye nemitya yokunxiba.

I-HONGSBELT iibhanti zokujika ezilandelelanayo, zinokufakwa kwindawo emanzi enobushushu obuphezulu, obufana nomphunga obushushu obungama-95°C.Sincoma iradiyasi yangaphakathi kufuneka ibe ngaphezu kwamaxesha ama-3 ububanzi bebhanti, kwaye i-engile ye-single okanye i-serial turning ayinakudlula i-180 °.Sinoyilo oluninzi lokwenyani kunye namava kwireferensi yakho;Nceda uqhagamshelane nesebe lethu lobuchule okanye iiarhente zalapha.

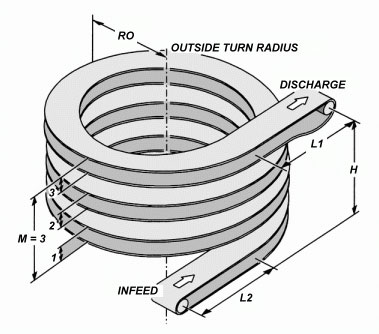

I-Spiral Conveyor

Xa i-spiral conveyor yohlobo lokubuyisela ibhanti kwindlela yokubuyisela lisebenza ngendlela yokuthutha kodwa kwicala elichaseneyo liyilwe ngokujika kothotho kwaye liqhutywe kwicala elinye, liyakwenza imilo njengegophe elijikelezayo.Kuzo zombini iziphelo zojiko olujikelezayo ziyafuneka ukuba zikhokele kwindlela ethe tye, emva koko iya kusebenza.Ubude obuncinci bendlela eqondileyo kufuneka bube ubuncinane amaxesha angama-1.5 ububanzi bebhanti yomthumeli, kwaye ayinakuba mfutshane kune-1000mm.

I-radius yangaphakathi ye-spiral conveyor ijikeleza kwi-360 degrees spiral;nikela ingqalelo kwinani leeleya ezingadluliyo ngaphezu kwe-3 umaleko, ikwabonisa ukuba i-engile ejikelezayo iyonke ye-spiral conveyor ayinakudlula ngaphezu kwe-1080 degrees.

Amanqaku e-Spiral Conveyor

Kwi-HONGSBELTserial iibhanti ezijikayo, ukuba i-radius yangaphakathi ingaphezulu kwe-2.5 ububanzi bebhanti, iya kwenza izandi ezingaqhelekanga ngenxa yesiganeko sokumisa kunye nokungcangcazela.Isiphelo esingenamsebenzi sebhanti asikwazanga ukushukuma de kubekho ukutsaleleka okwaneleyo ukoyisa ingxabano phakathi kwebhanti kunye nendlela yokuthwala.Le ngxolo inokupheliswa ngokuthatha igrisi okanye ulwelo lwesepha ukuthambisa iileyili kunye nemitya yokunxiba.

Ifomula yokubala yeRadi yangaphandle yeSpiral Conveyor

Umzekeliso ongezantsi yifomula yokubala ngaphandle/ngaphakathi kweradiyasi yebhanti lokuhambisa elijikelezayo.

IFOMU:

Ubude bebhanti lokuhambisa = 2B+ ( sprocket ubukhulu x 3.1416 )

A = D × 3.1416 × P ( X )

B = ( √ H2 + A2 ) + L1 + L2, B = A / Cos DEG.okanye B = H / Tan DEG.

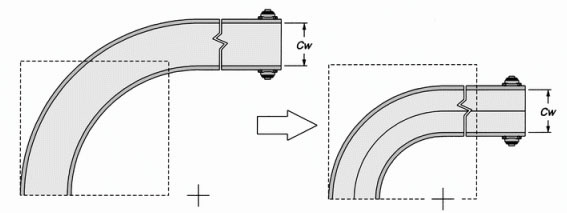

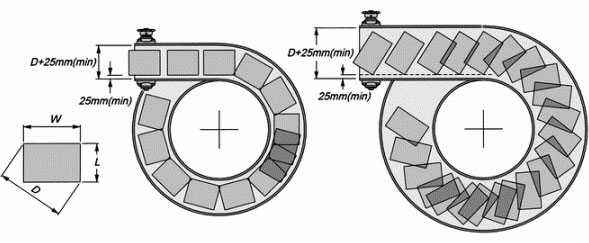

Nciphisa Ngaphakathi Radius

Kukho izithintelo ezininzi ezingqongqo kwiradiyasi yangaphakathi ye-HONGSBELT yokujika amabhanti.Xa uyila kunye nokuvelisa amabhanti okujika, ingxaki yendawo yefektri iya kudibana nayo yonke ixesha.Umzi-mveliso awukwazi ukwamkela umhambisi omkhulu wokuthutha;kuyimfuneko ukunciphisa i-radius yangaphakathi yebhanti.Inokuthi ithathe imiqolo emibini yeebhanti okanye imiqolo emininzi yoyilo lwebhanti kwicandelo lokujika ukuze ithathe indawo yebhanti enye, ukoyisa ingxaki yobubanzi obugqithisileyo ngaphakathi ngaphakathi.Nangona kunjalo, olu luyilo lunokubangela ukuba isantya sebhanti yangaphandle sicothe kunebhanti yangaphakathi.Nceda uqaphele ukuba oku kuya kuchaphazela ukusebenza kakuhle kwenkqubo yokuhambisa okanye hayi.

Umzekelo woYilo

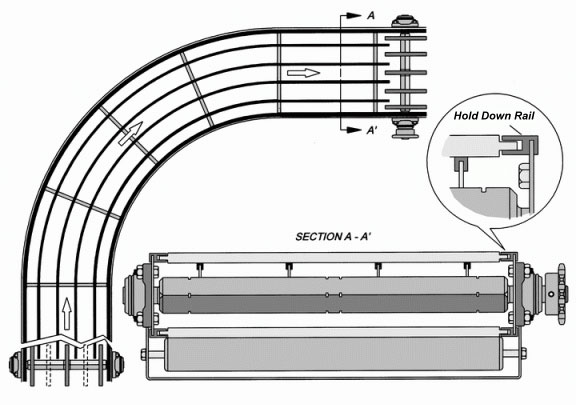

Umzekelo wokubamba uFakelo lukaloliwe

Ukubamba Umzila kaloliwe wenziwa ngezinto zeHDPE.Ufakelo lwe-Hold Down Rail kwi-C shape rabbet inxalenye kufuneka ihambelane nefreyimu yentsimbi kwicala le-conveyor, ulandele kunye ne-radian kwaye uyifake, ukugqiba ukufakela.Kwindawo yokusebenza yobushushu obuphantsi, iyafumaneka ukusebenzisa isifudumezi serhasi okanye isifudumezi sombane somoya ukuyifudumeza ukuya kuthi ga kwi-100 ~ 120℃ kwaye igobe ngendlela efanelekileyo ukuze ilingane nofakelo olufunekayo.

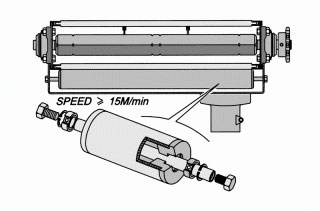

Isantya sokuSebenza

Ibhanti iya kuba nemeko yokufumba ngendlela yokubuyisela, kwaye ibangele ukuba ibhanti liphumle kwaye lingcangcazele.Ke ngoko, xa isantya sokusebenza siphezulu kune-20M ngomzuzu, yamkela iirola ezithwele ibhola ukuze zithathe indawo yokubamba iileyili kwindawo yokubuya iya kusombulula ingxaki.

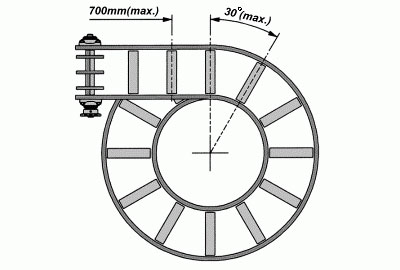

Isithuba soMda weNdlela yokuBuyisa

Xa ujika isixokelelwano sebhanti lokuhambisa sebenzisa iirola ezithwele ibhola ukuxhasa indlela yokubuya, ikhefu phakathi kweerola kwindawo ethe tye kufuneka libe lincinci kune-650mm.I-angle ebandakanyiweyo kwicandelo lokujika alikho ngaphezu kwe-30 degree okanye ubude be-curve yangaphandle abukho ngaphezu kwe-600mm, umyinge we-angle edibeneyo.Kuya kuba ne-avareji yoqhagamshelwano ngakumbi kwindawo xa i-roller indlela yokubuya ixhasa ibhanti.Ukuba ubude be-curve yangaphandle bungaphezulu kwe-600 mm ye-roller interval, kufuneka ifake isikhokelo sesilayidi esixhasayo (UHMW) ukuqinisekisa ukuzinza kwe-operatipn yendlela yokubuya.

Amanqaku obubanzi bebhanti

Xa iimveliso zilayisha kwindlela yokuthutha yokuguqula inkqubo yokuhambisa, ziya kulandela intshukumo yelayini yomhambisi ukuya phambili.Iimveliso azijikelezi kumphezulu webhanti ngenxa yesantya somgca webhanti lokuhambisa likwintshukumo yekonsathi ngexesha lokuthutha.Ke ngoko, xa uyila inkqubo yebhanti yokuhambisa, ububanzi bebhanti kufuneka bube bukhulu kunobubanzi bemveliso yokuthwala.