Amalungiselelo

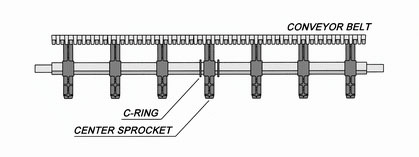

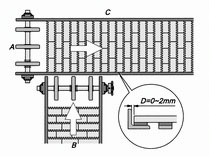

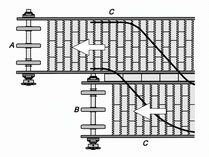

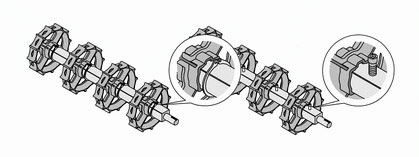

I-sprocket yeziko kufuneka ibekwe kwindawo ephakathi yobubanzi bebhanti yokuhambisa, ukuqinisekisa ukuba isalathiso sokuthutha siya kugcina intshukumo ehambelanayo ngexesha lokuhambisa umqhubi.I-drive / i-Idle sprockets kufuneka ilungiswe yi-C igcina amakhonkco emacaleni omabini, ukuqinisekisa ukuba i-sprockets itshixiwe kwindawo efanelekileyo.Ezi sprockets ezigcinayo ziya kubonelela ngomkhondo ochanekileyo wokugcina ibhanti lisebenza ngokufanelekileyo phakathi kweefreyimu ezisemacaleni zomhambisi.

Ngaphandle kwe-sprocket yeziko kufuneka ibekwe kwindawo ephakathi kwe-shaft, ezinye ii-sprockets azidingeki ukuba zilungiswe;bavunyelwe ukuba bakhululeke ukubandakanya ibhanti kwimeko yokwandiswa kwe-thermal kunye nokunciphisa.Le ndlela yokuqhuba inokuthintela ukubandakanyeka okungalunganga kwebhanti kunye ne-sprockets.

Ngokuphathelele kulungiselelo lwezithuba phakathi kwesprockets, nceda ubhekisele kwiSprocket Spacing kwimenyu esekhohlo.

ULungiselelo lweSprocket lokuJika ibhanti leConveyor

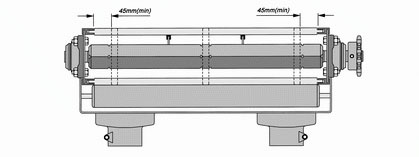

Ngelixa ulungiselela i-sprockets, isithuba asiyi kuba ngaphezu kwe-145mm kwaye i-sprocket ephakathi kufuneka ilungiswe ngamakhonkco okugcina.

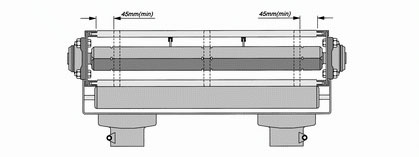

Xa ubude benkqubo yokuthutha bungaphantsi kwamaxesha ama-4 ububanzi bebhanti, isithuba asikho ngaphezu kwe-90mm.Isithuba phakathi kwe-sprocket yangaphandle kunye ne-belt edge kufuneka ibe ngaphezu kwe-45mm.

Ngokuphathelele kulungiselelo lwezithuba phakathi kwesprockets, nceda ubhekisele kwiSprocket Spacing kwimenyu esekhohlo.

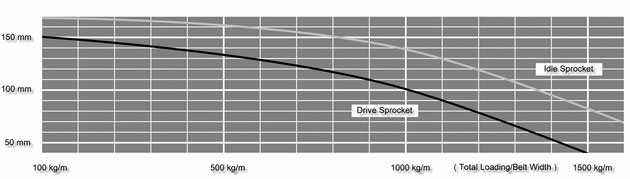

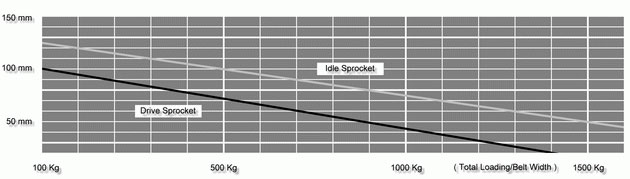

ISazobe seSprocket seSithuba sothotho lwe-100

Amanqaku

Igrafu engentla yidatha yezithuba zeziko le-sprocket;ezi datha luqikelelo kunye nereferensi kuphela.Nceda ubeke phambili eyona ndawo yokuba ii-sprockets zisebenzisana nebhanti ngelixa kuyilwa kwaye kusetyenzwa.

Nceda ubhekisele kwidatha yegophe kwaye usete izithuba ngelixa ufaka i-sprockets.Kufuneka yabiwe ngokwe-avareji kwaye incinci kunedatha yegophe.

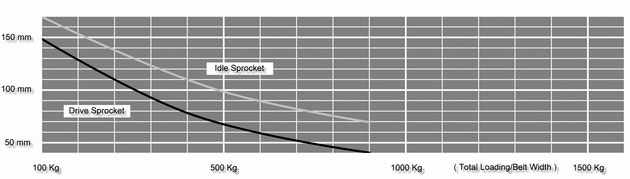

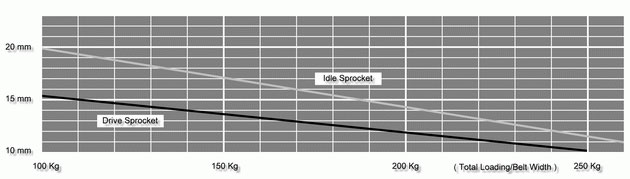

ISazobe seSithuba seSprocket seSeries 200

Amanqaku

Igrafu engentla yidatha yezithuba zeziko le-sprocket;ezi datha luqikelelo kunye nereferensi kuphela.Nceda ubeke phambili eyona ndawo yokuba ii-sprockets zisebenzisana nebhanti ngelixa kuyilwa kwaye kusetyenzwa.

Nceda ubhekisele kwidatha yegophe kwaye usete izithuba ngelixa ufaka i-sprockets.Kufuneka yabiwe ngokwe-avareji kwaye incinci kunedatha yegophe.

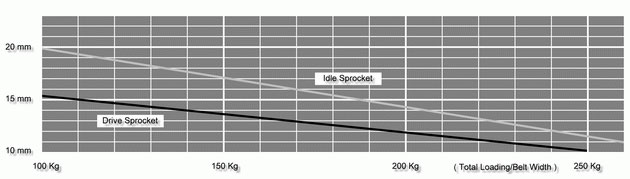

ISazobe seSithuba seSprocket seSeries 300

Amanqaku

Igrafu engentla yidatha yezithuba zeziko le-sprocket;ezi datha luqikelelo kunye nereferensi kuphela.Nceda ubeke phambili eyona ndawo yokuba ii-sprockets zisebenzisana nebhanti ngelixa kuyilwa kwaye kusetyenzwa.

Nceda ubhekisele kwidatha yegophe kwaye usete izithuba ngelixa ufaka i-sprockets.Kufuneka yabiwe ngokwe-avareji kwaye incinci kunedatha yegophe.

ISazobe seSithuba seSprocket seSeries 400

Amanqaku

Igrafu engentla yidatha yezithuba zeziko le-sprocket;ezi datha luqikelelo kunye nereferensi kuphela.Nceda ubeke phambili eyona ndawo yokuba ii-sprockets zisebenzisana nebhanti ngelixa kuyilwa kwaye kusetyenzwa.

Nceda ubhekisele kwidatha yegophe kwaye usete izithuba ngelixa ufaka i-sprockets.Kufuneka yabiwe ngokwe-avareji kwaye incinci kunedatha yegophe.

ISprocket Spacing Diagram yeSeries 500

Amanqaku

Igrafu engentla yidatha yezithuba zeziko le-sprocket;ezi datha luqikelelo kunye nereferensi kuphela.Nceda ubeke phambili eyona ndawo yokuba ii-sprockets zisebenzisana nebhanti ngelixa kuyilwa kwaye kusetyenzwa.

Nceda ubhekisele kwidatha yegophe kwaye usete izithuba ngelixa ufaka i-sprockets.Kufuneka yabiwe ngokwe-avareji kwaye incinci kunedatha yegophe.

cross & parallel

Ngethuba lokusetyenziswa kwamabhanti okuhambisa ukudibanisa, kufuneka kuthathelwe ingqalelo ekhethekileyo indlela emiselweyo ye-sprockets.

Xa umhambisi u-B edibana no-A, i-sprocket ye-conveyor A ekufutshane ne-conveyor B kufuneka ilungiswe.Ngaphandle koko, ixabiso le-D le-conveyor A (Itheyibhile 9) kufuneka lincitshiswe, kwaye izithuba kufuneka zongezwe kwixabiso le-D lecala le-C. Zonke ukunyamezela kwandiswa kwe-conveyor A zigcinwe kwicala le-C ukuze kufumaneke umphumo ongcono wokudibanisa.

ULungiselelo lweSprocket loQhagamshelwano oluFanayo lwabaThuthi

Ngethuba lokusetyenziswa kwamabhanti okuhambisa ukudibanisa okufanayo, kufuneka kuthathelwe ingqalelo ekhethekileyo ekulungiseni i-sprocket ye-drive ye-conveyors zombini kwicala elisondeleyo komnye umthuthi.Ngexabiso elingu-D, nceda ubhekisele kumzekeliso okhankanywe ngasentla, kwaye ugcine isithuba sonyamezelo olwandisiweyo kwicala C ukuze uvumele isithuba phakathi kwefreyimu yabahambisi ababini sehliselwe kowona mda usezantsi xa ubushushu buguquka.

Idle Sprocket

IzikoI-sprocket ye-shaft engasebenziyo kufuneka ilungiswe ngamakhonkco okugcina, ukuqinisekisa ukuba ulwalathiso lokuthutha luya kuba luthe ngqo ngaphandle kwe-slanting.Inani lee-drive sprockets minus 2 linani lee-sprockets ezingasebenziyo.Isithuba kufuneka sabiwe ngokomndilili kwishaft.Ubuninzi bee-sprockets ezingasebenziyo azikwazi ukuba ngaphantsi kwamaqhekeza ama-3.Nceda ujonge kwiSithuba seSprocket kwimenyu yasekhohlo.

ULungiselelo lwe-Idle Sprocket yokuJika ibhanti leConveyor

Isithuba se-sprocket kwi-shaft engasebenziyo asiyi kuba ngaphezu kwe-150mm ngexesha loyilo.Ukuba isixokelelwano sokuhambisa siyilwe kwi-bidirectional conveyance, ilungiselelo le-sprockets elingasebenziyo kufuneka lifane ne-drive sprockets.Nceda ujonge kwiSithuba seSprocket kwimenyu yasekhohlo.

Ukusebenza okwethutyana

Ngelixa umthumeli ekwimeko yokusebenza kwethutyana, kuya kuba lula ukwenzeka into yokutshintsha ibhanti kumacala omabini kwaye kubangele ukubandakanyeka okungafanelekanga phakathi kwebhanti kunye ne-sprockets.I-sprockets yamahhala iya kutshintshela kumacala omabini e-shaft ngenxa yokuba ayilungiswanga ngamakhonkco okugcina.Ukuba imeko ayilungiswanga, iya kuba nefuthe ekusebenzeni komqhubi.

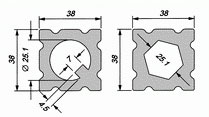

I-Adapter eneHexagonal

Ukuhambisa imveliso elula, i-drive/i-shaft engasebenziyo inokwamkela iadaptha engqukuva endaweni yokusetyenzwa kwe-square shaft.Kunconywa ukufaka isicelo kwindawo yokusebenza yokulayisha ukukhanya kunye nebhanti ububanzi obungaphakathi kwe-450mm.

Imisesane yokugcina

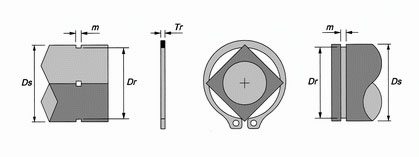

| DS | Ikhowudi | m | Tr | Dr | |

| Isikwere | 38 mm | 52 | 2.2 mm | 2 mm | 47.8 mm |

| 50 mm | 68 | 2.7 mm | 5 mm | 63.5 mm | |

| 64 mm | 90 | 3.2 mm | 3 mm | 84.5 mm | |

| Umjikelo | ?30 mm | 30 | 1.8 mm | 1.6 mm | 27.9 mm |

| ?45 mm | 45 | 2.0 mm | 1.8 mm | 41.5 mm | |