Uguqulo lweeYunithi

| IsiNgesi (eUSA) iYunithi X | Phinda-phinda nge | = Iyunithi yeMetric | X Phinda-phinda nge | = Iyunithi yesiNgesi (eUSA). | ||

| Umlinganiselo womgca | in | 25.40 | mm | 0.0394 | in | Umlinganiselo womgca |

| in | 0.0254 | m | 39.37 | in | ||

| ft | 304.8 | mm | 0.0033 | ft | ||

| ft | 0.3048 | m | 3.281 | ft | ||

| Umlinganiselo wesikwere | kwi2 | 645.2 | mm2 | 0.00155 | kwi2 | Umlinganiselo wesikwere |

| kwi2 | 0.000645 | m2 | 1550.0 | kwi2 | ||

| ft2 | 92.903 | mm2 | 0.00001 | ft2 | ||

| ft2 | 0.0929 | m2 | 10.764 | ft2 | ||

| Umlinganiselo weCubic | ft3 | 0.0283 | m3 | 35.31 | ft3 | Umlinganiselo weCubic |

| ft3 | 28.32 | L | 0.0353 | ft3 | ||

| Isantya sesantya | ft/s | 18.29 | m/umz | 0.0547 | ft/s | Isantya sesantya |

| ft / min | 0.3048 | m/umz | 3.281 | ft / min | ||

| Avoirdupois Ubunzima | lb | 0.4536 | kg | 2.205 | lb | Avoirdupois Ubunzima |

| lb/ft3 | 16.02 | kg / m3 | 0.0624 | lb/ft3 | ||

| Ukuthwala Umthamo | lb | 0.4536 | kg | 2.205 | lb | Ukuthwala Umthamo |

| lb | 4.448 | Newton (N) | 0.225 | lb | ||

| kg | 9.807 | Newton (N) | 0.102 | kg | ||

| lb / ft | 1.488 | kg / m | 0.672 | lb / ft | ||

| lb / ft | 14.59 | N / m | 0.0685 | lb / ft | ||

| kg - m | 9.807 | N / m | 0.102 | kg - m | ||

| Torque | kwi-lb | 11.52 | kg - mm | 0.0868 | kwi-lb | Torque |

| kwi-lb | 0.113 | N - m | 8.85 | kwi-lb | ||

| kg - mm | 9.81 | N - mm | 0.102 | kg - mm | ||

| Jikelezisa inertia | kwi4 | 416.231 | mm4 | 0.0000024 | kwi4 | Jikelezisa inertia |

| kwi4 | 41.62 | cm4 | 0.024 | kwi4 | ||

| Uxinzelelo / Uxinzelelo | lb/nge2 | 0.0007 | kg / mm2 | 1422 | lb/nge2 | Uxinzelelo / Uxinzelelo |

| lb/nge2 | 0.0703 | kg / cm2 | 14.22 | lb/nge2 | ||

| lb/nge2 | 0.00689 | N/ mm2 | 145.0 | lb/nge2 | ||

| lb/nge2 | 0.689 | N/cm2 | 1.450 | lb/nge2 | ||

| lb/ft2 | 4.882 | kg / m2 | 0.205 | lb/ft2 | ||

| lb/ft2 | 47.88 | N/m2 | 0.0209 | lb/ft2 | ||

| Amandla | HP | 745.7 | watt | 0.00134 | HP | Amandla |

| ft - lb / min | 0.0226 | watt | 44.25 | ft - lb / min | ||

| Ubushushu | °F | TC = ( °F - 32) / 1.8 | Ubushushu | |||

Uphawu lwe-BDEF

| Uphawu | Iyunithi | |

| BS | Conveyor Belt Tensile Amandla | Kg/M |

| BW | Ububanzi bebhanti | M |

C Uphawu Ingcaciso

| Uphawu | Iyunithi | |

| Ca | Jonga iTheyibhile FC | ---- |

| Cb | Jonga iTheyibhile FC | ---- |

D Uphawu Inkcazo

| Uphawu | Iyunithi | |

| I-DS | I-Shaft Deflection ratio | mm |

E Uphawu Inkcazo

| Uphawu | Iyunithi | |

| E | Inqanaba lokwandiswa kweShaft | Gpa |

F Uphawu Inkcazelo

| Uphawu | Iyunithi | |

| FC | I-Friction Coefficient phakathi kwe-Belt Edge kwaye ubambe i-Strip | ---- |

| FBP | I-Friction Coefficient phakathi kwe-Carry Product kunye ne-Belt Surface | ---- |

| FBW | I-Friction Coefficient ye-Belt Support Material | ---- |

| FA | I-Coefficient ilungisiwe | ---- |

| FS | I-Tensile Strength Coefficient ihlonyelwe | ---- |

| FT | I-Conveyor Belt i-Temperature Coefficient ilungisiwe | --- |

Uphawu lwe-HILM

| Uphawu | Iyunithi | |

| H | Umphakamo weConveyor uthambekele ukuphakama. | m |

| HP | Amandla ehashe | HP |

I Uphawu Inkcazelo

| Uphawu | Iyunithi | |

| I | Umzuzu we-inertia | mm4 |

L Inkcazo yophawu

| Uphawu | Iyunithi | |

| L | Umgama wokuHambisa (iNdawo esembindini ukusuka kwi-Drive Shaft ukuya kwi-Idler Shaft) | M |

| LR | Buyela ngendlela eNgqo Qhuba ubude beCandelo | M |

| LP | Qhuba Indlela eNgqo Qhuba ubude beCandelo | M |

M uphawu Inkcazo

| Uphawu | Iyunithi | |

| M | Inqanaba leNqanaba le-Spiral Conveyor | ---- |

| MHP | Amandla eeMotor | HP |

Uphawu lwePRS

| Uphawu | Iyunithi | |

| PP | Imveliso eqokelelweyo yoMlinganiselo weNdawo yepesenti yeCarry Way | ---- |

R Uphawu Inkcazo

| Uphawu | Iyunithi | |

| R | Sprocket Radius | mm |

| RO | Ngaphandle kweRadiyosi | mm |

| rpm | Uguqulo ngomzuzu | rpm |

S Symbol Inkcazo

| Uphawu | Iyunithi | |

| SB | Isithuba phakathi kokuBeka | mm |

| SL | I-Shaft iyonke iyalayisha | Kg |

| SW | Ubunzima beShaft | Kg/M |

Uphawu lweTVW

| Uphawu | Iyunithi | |

| TA | IYunithi yeBhanti yoMhambisi eVukelelekileyo | Kg/M |

| TB | Conveyor Belt Unit Theory Tension | Kg/M |

| TL | Iyunithi ye-Conveyor Belt Catenary's Sag tension. | Kg/M |

| TN | Uxinzelelo lweCandelo | kg/M |

| TS | Torque | Kg.mm |

| TW | IYunithi yeBhanti yoMhambisi iyonke yoxinzelelo | Kg/M |

| TWS | IYunithi yeBhanti yoMhambisi wodidi oluKhethekileyo Iyonke Uxinzelelo | Kg/M |

V iSimboli Ingcaciso

| Uphawu | Iyunithi | |

| V | Isantya sokuHambisa | M/umz |

| VS | Isantya sethiyori | M/umz |

W Inkcazo yophawu

| Uphawu | Iyunithi | |

| WB | Conveyor Belt Unit Weight | Kg/M2 |

| Wf | Uxinzelelo lweFriction oluqokelelweyo | Kg/M2 |

| WP | Conveyor Belt Carry Product Unit Weight |

|

IPusher kunye neBidirectional

Kwi-pusher okanye i-bidirectional conveyor, ukunyanzeliswa kwebhanti kuya kuba phezulu kune-conveyor eqhelekileyo ethe tye;ngoko ke, i-shafts kwiziphelo ezimbini ziyimfuneko ukuba zithathwe njenge-drive shafts kwaye zifakwe ekubaleni.Ngokubanzi, kuqikelelwa amaxesha angama-2.2 amava okufumana uxinzelelo olupheleleyo lwebhanti.

IFOMU: TWS = 2.2 TW = 2.2 TB X FA

I-TWS kule yunithi ithetha ukubalwa koxinzelelo lwe-bidirectional okanye isiqhubi sokuhambisa.

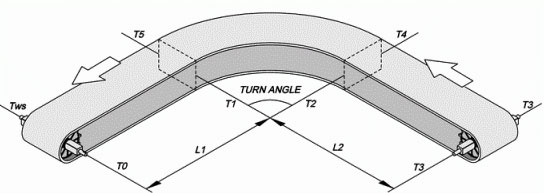

Ukuguqula ukubala

Ubalo loxinzelelo lwe-TWS yesidluliseli esijikayo kukubala uxinzelelo oluqokelelweyo.Ke ngoko, uxinezeleko kwicandelo ngalinye elithweleyo liya kuchaphazela ixabiso loxinzelelo lulonke.Oko kuthetha ukuba, ukunyanzeliswa okupheleleyo kuqokelelwe ukususela ekuqaleni kwecandelo lokuqhuba ngendlela yokubuyisela, kunye nendlela yokubuyela kwindawo ye-idler, kwaye emva koko udlule kwicandelo lokuthwala ukuya kwicandelo lokuqhuba.

Indawo yoyilo kule yunithi yi-T0 ephantsi kwe-drive shaft.Ixabiso lika T0 lilingana noziro;sibala icandelo ngalinye ukusuka kwi-T0.Umzekelo, icandelo lokuqala elithe ngqo kwindlela yokubuyisela lisuka ku-T0 ukuya kwi-T1, kwaye oko kuthetha ukuba uxinzelelo oluqokelelweyo lwe-T1.

I-T2 yintlupheko eqokelelweyo yendawo yokujika kwindlela yokubuya;kwelinye igama, luxinzelelo oluqokelelweyo lwe-T0, T1 kunye ne-T2.Nceda ngokomfanekiso ongasentla kwaye ucinge ngoxinzelelo oluqokelelweyo lwamacandelo okugqibela.

IFOMU: TWS = ( T6 )

Uxinzelelo olupheleleyo lwecandelo lokuqhuba kwindlela yokuthwala.

I-TWS kule yunithi ithetha ukubalwa koxinzelelo lwesihambisi esijikayo.

IFOMU: T0 = 0

T1 = WB + FBW X LR X WB

Uxinzelelo lwe-catenary sag kwindawo yokuqhuba.

IFOMU: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X WB

Uxinzelelo lwecandelo lokujika kwindlela yokubuya.

Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc.

T2 = ( Ca X T2-1 ) + ( Cb X FBW X RO ) X WB

TN = ( Ca X T1 ) + ( Cb X FBW X RO ) X WB

IFOMU: TN = TN-1 + FBW X LR X WB

Uxinzelelo lwecandelo elithe tye kwindlela yokubuya.

T3 = T3-1 + FBW X LR X WB

T3 = T2 + FBW X LR X WB

IFOMU: TN = TN-1 + FBW X LP X ( WB + WP )

Uxinzelelo lwecandelo elithe tye kwindlela yokuthwala.

T4 = T4-1 + FBW X LP X ( WB + WP )

T4 = T3 + FBW X LP X ( WB + WP )

IFOMU: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

Uxinzelelo lwecandelo lokujika kwindlela yokuthwala.

Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc.

T5 = ( Ca X T5-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

T5 = ( Ca X T4 ) + ( Cb X FBW X RO ) X ( WB + WP )

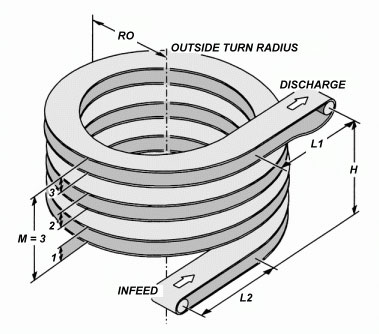

I-Spiral Conveyor

IFOMU: TWS = TB × FA

I-TWS kule yunithi ithetha ukubalwa koxinzelelo lwe-spiral conveyor.

IFOMU: TB = [ 2 × RO × M + ( L1 + L2 )] ( WP + 2WB ) × FBW + ( WP × H )

IFOMU: TA = BS × FS × FT

Nceda ubhekisele kwiTheyibhile FT kunye neTheyibhile yeFS.

Umzekelo Oluncedo

Ukuthelekiswa kwe-TA kunye ne-TB, kunye nezinye izibalo ezinxulumene nazo ziyafana nezinye iintlobo zokuhambisa.Kukho izithintelo ezithile kunye nemimiselo yoyilo kunye nokwakhiwa kwe-spiral conveyor.Ke ngoko, ngelixa usebenzisa i-HONGSBELT spiral okanye ukuguqula amabhanti kwi-spiral conveyor system, sicebisa ukuba ubhekisele kwi-HONGSBELT Engineering manual kwaye uqhagamshelane nesebe lethu lenkonzo yobugcisa ngolwazi oluthe vetshe kunye neenkcukacha.

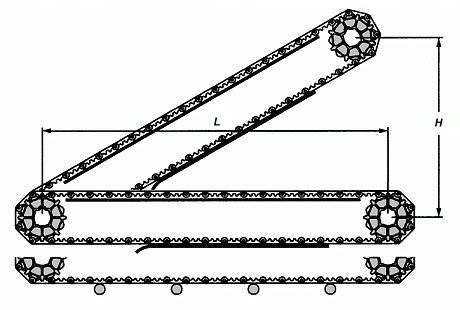

Uxinzelelo lweyunithi

IFOMU: TB = [ ( WP + 2WB ) X FBW ] XL + ( WP XH )

Ukuba ukuthwala iimveliso kunophawu lokufumba, amandla okruthakruthwano e-Wf athe anyuka ngexesha lokupakishwa kokuhanjiswa kufuneka athathelwe kubalo.

IFOMU: TB = [ ( WP + 2WB ) X FBW + Wf ] XL + ( WP XH )

IFOMU: Wf = WP X FBP X PP

Uxinzelelo oluvumelekileyo

Ngenxa yezinto ezahlukeneyo zebhanti zinamandla ahlukeneyo okuxinana okuya kuchaphazeleka ngokuhluka kweqondo lokushisa.Ngoko ke, ukubalwa kweyunithi ye-tension evumelekileyo ye-TA ingasetyenziselwa ukungafani nebhanti ye-tension ye-TW.Esi siphumo sokubala siya kukunceda wenze ukhetho olufanelekileyo lokukhetha ibhanti kwaye ufanise iimfuno zomhambisi.Nceda ubhekisele kwiTheyibhile FS kunye neTheyibhile Ts kwimenyu esekhohlo.

IFOMU: TA = BS X FS X FT

BS = Amandla oMbane weBhanti yoMhambisi ( Kg / M )

FS kunye FT Jonga kwiTheyibhile FS kunye neTheyibhile FT

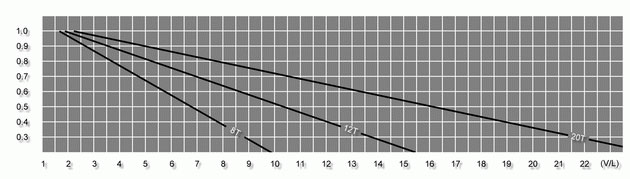

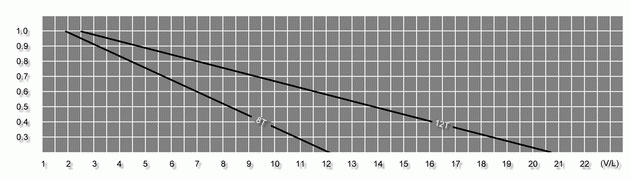

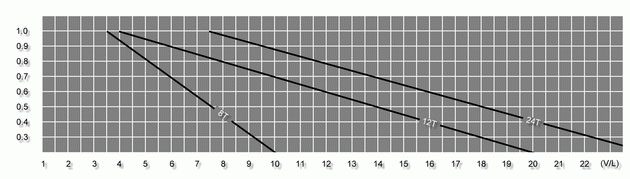

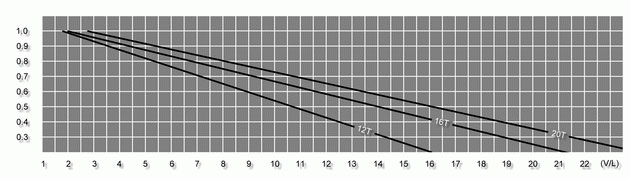

Uluhlu Fs

Uthotho HS-100

Uthotho HS-200

Uthotho HS-300

Uthotho HS-400

Uthotho HS-500

Itheyibhile Ts

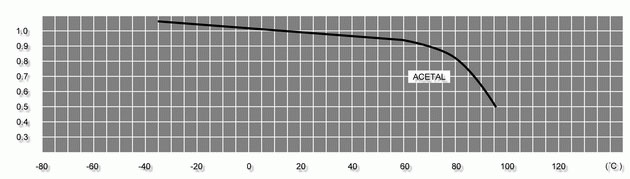

Acetal

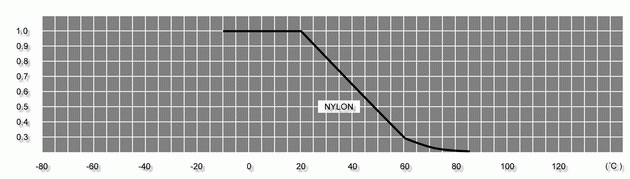

Inayiloni

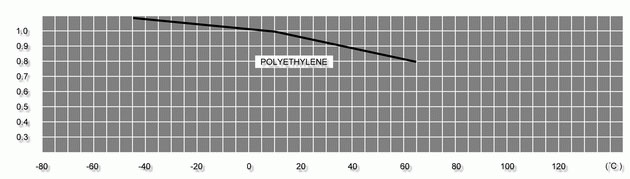

Polyethylene

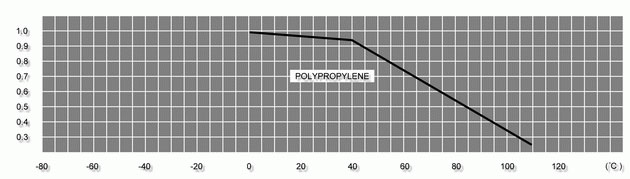

Polypropylene

Ukukhethwa kweShaft

IFOMU: SL = ( TW + SW ) ?BW

Iqhutywa / Idler Shaft Weight Table - SW

| Shaft Imilinganiselo | Ubunzima beShaft ( Kg/M ) | |||

| Intsimbi yeCarbon | Yenziwe ngentsimbi eshayinayo | Ingxubevange yeAluminiyam | ||

| Ishafu yesikwere | 38mm | 11.33 | 11.48 | 3.94 |

| 50mm | 19.62 | 19.87 | 6.82 | |

| Round Shaft | 30mm?/FONT> | 5.54 | 5.62 | 1.93 |

| 45mm?/FONT> | 12.48 | 12.64 | 4.34 | |

Ukuphambuka kwe-Drive / Idler Shaft-DS

Ngaphandle koKuthwala okuPhakathi

IFOMU :

DS = 5 ?10-4 ( SL ?SB3 / E ?/FONT> I )

Ngokuthwala okuPhakathi

IFOMU :

I-DS = 1 ?10-4 ( SL ?SB3 / E ?I )

Ukunyameka kwe-Drive Shaft - E

| Iyunithi: Kg/mm2 | |||

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo | Intsimbi yeCarbon | Ingxubevange yeAluminiyam |

| Qhuba iShaft Elastic Rate | 19700 | 21100 | 7000 |

Umzuzu we-Iertia - I

| Bore diameter of drive sprocket | Umzuzu we-inetia yeshaft ( mm4 ) | |

| I-Square Shaft | 38mm | 174817 |

| 50mm | 1352750 | |

| Round Shaft | 30mm?/FONT> | 40791 |

| 45mm?/FONT> | 326741 | |

Qhuba iShaft Torque Calculation - TS

| IFOMU : | TS = TW ?BW ?R |

Ngexabiso lokubala elingentla, nceda uthelekise netheyibhile engezantsi ukuze ukhethe eyona shaft yokuqhuba.Ukuba i-torque ye-drive shaft isenamandla kakhulu, i-sprocket encinci ingasetyenziselwa ukunciphisa i-torque, kwaye iphinde ihlawule iindleko eziphambili ze-shaft kunye nokuthwala.

Ukusebenzisa i-sprocket encinci ukulingana ishaft yokuqhuba enobubanzi obukhulu ukunciphisa itorque, okanye ukusebenzisa i-sprocket enkulu ukulingana ishaft yokuqhuba enobubanzi obuncinci ukunyusa itorque.

Ubuninzi beTorque Factor yeDrive Shaft

| Torque | Izinto eziphathekayo | Ububanzi beJenali (mm) | ||||||

| 50 | 45 | 40 | 35 | 30 | 25 | 20 | ||

| Kg-mm x 1000 | Yenziwe ngentsimbi eshayinayo | 180 | 135 | 90 | 68 | 45 | 28 | 12 |

| Intsimbi yeCarbon | 127 | 85 | 58 | 45 | 28 | 17 | 10 | |

| Ingxubevange yeAluminiyam | -- | -- | -- | 28 | 17 | 12 | 5 | |

Amandla ehashe

Ukuba i-motor ye-drive ikhethelwe i-motor yokunciphisa i-gear, umlinganiselo wamandla ehashe kufuneka ube mkhulu kuneemveliso ezithweleyo kunye ne-total force force eyenziwa ngexesha lokuqhuba ibhanti.

Amandla eHashe (HP)

| IFOMU : | = 2.2 × 10-4 × TW × BW × V |

| = 2.2 × 10-4 ( TS × V / R ) | |

| = Watts × 0.00134 |

Watts

| IFOMU : | = ( TW × BW × V ) / ( 6.12 × R ) |

| = ( TS × V ) / ( 6.12 × R ) | |

| = HP × 745.7 |

Itafile FC

| Izinto zikaloliwe | Ubushushu | FC | ||

| Ibhanti Material | Yomile | Imanzi | ||

| HDPE / UHMW | -10°C ~ 80°C | PP | 0.10 | 0.10 |

| PE | 0.30 | 0.20 | ||

| Actel | 0.10 | 0.10 | ||

| Inayiloni | 0.35 | 0.25 | ||

| Acetal | -10°C ~ 100°C | PP | 0.10 | 0.10 |

| PE | 0.10 | 0.10 | ||

| Actel | 0.10 | 0.10 | ||

| Inayiloni | 0.20 | 0.20 | ||

Nceda uthelekise izinto zomzila kunye nebhanti yokuhambisa kunye nenkqubo yokuthutha kwindawo eyomileyo okanye emanzi ukuze ufumane ixabiso le FC.

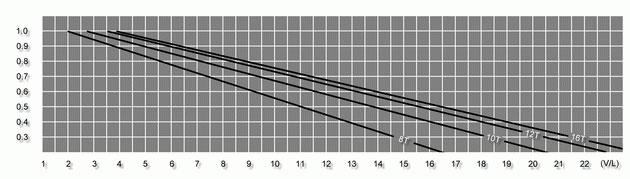

Ca, Ixabiso leCb

| Ibhanti yokuhambisa iEngile | I-Friction Coefficient phakathi kwe-Conveyor Belt Edge kunye ne-Rail Strip | |||||

| FC ≤ 0.15 | FC ≤ 0.2 | FC ≤ 0.3 | ||||

| Ca | Cb | Ca | Cb | Ca | Cb | |

| ≥ 15 ° | 1.04 | 0.023 | 1.05 | 0.021 | 1.00 | 0.023 |

| ≥ 30 ° | 1.08 | 0.044 | 1.11 | 0.046 | 1.17 | 0.048 |

| ≥ 45 ° | 1.13 | 0.073 | 1.17 | 0.071 | 1.27 | 0.075 |

| ≥ 60 ° | 1.17 | 0.094 | 1.23 | 0.096 | 1.37 | 0.10 |

| ≥ 90 ° | 1.27 | 0.15 | 1.37 | 0.15 | 1.6 | 0.17 |

| ≥ 180 ° | 1.6 | 0.33 | 1.88 | 0.37 | 2.57 | 0.44 |

Emva kokufumana ixabiso le-FC kwi-Table FC, nceda uthelekise kunye ne-angle egobileyo ye-conveyor, kwaye unokufumana ixabiso le-Ca kunye nexabiso le-Cb.