Umhambisi othe tye

Kwifektri yokumisa inyama, ubushushu be-ambient bulawulwa kwi-21 ° C, kwaye yamkelwe i-HS-100 yomgca wokumisa inyama.Ubunzima obuqhelekileyo benyama yi-60kg/M2.Ububanzi bebhanti yi-600mm, kwaye ubude obupheleleyo bomthumeli ngu-30M kwi-design ethe tye.Isantya sokusebenza sebhanti lokuhambisa yi-18M/min kwindawo yokufuma nokubanda.Umhambisi uqala ekothuleni kwaye akukho mqathango wandayo.Yamkela i-sprockets enamazinyo ayi-8 kwi-192mm ububanzi, kunye ne-38mm x 38mm ye-stainless steel drive shaft.Ifomula yokubala efanelekileyo yile ilandelayo.

Ukubalwa koxinzelelo lwethiyori yeyunithi - TB

| IFOMU : | TB =〔 ( WP + 2 WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔 ( 60 + ( 2 × 8.6 ) × 0.12 〕× 30 = 278 (kg / M) | |

| Ngenxa yokuba ayilulo ukuhanjiswa kwemfumba, iWf inokungahoywa. |

Ukubalwa kweyunithi yoxinzelelo lulonke - TW

| IFOMU : | TW = TB × FA |

| TW = 278 × 1.0 = 278 ( Kg / M ) |

Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

| TA = 1445 × 1.0 × 0.95 = 1372.75 ( Kg / M ) | |

| Ngenxa yexabiso le-TA likhulu kune-TW, Ngoko ke, ukwamkela nge-HS-100 kukhetho olufanelekileyo. |

Nceda ubhekisele kwisithuba seSprocket se-HS-100 kwiSahluko se-Drive Sprockets;isithuba esikhulu se-sprocket simalunga ne-140mm kolu yilo.Zombini i-drive/Idler end of conveyor kufuneka ibekwe nge-3 sprockets.

-

I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TW + SW ) × BW |

| SL = ( 278 + 11.48 ) × 0.6 = 173.7 ( Kg ) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi ye-Shaft Selection, siyazi ukuba ukusetyenziswa kwe-38mm × 38mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. | |

| IFOMU : | DS = 5 × 10-4 × ( SL x SB3 / E x I ) |

| DS = 5 × 10-4 × [ (173.7 × 7003 ) / ( 19700 × 174817 )] = 0.0086 | |

| Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo. |

-

Ukubalwa kwe-shaft torque - TS

| IFOMU : | TS = TW × BW × R |

| TS = 10675 ( kg - mm ) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi yokuKhethwa kweShaft, siyazi ukuba ukusetyenziswa kwe-50mm × 50mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

-

Ukubalwa kwamandla eHashe - HP

| IFOMU : | HP = 2.2 × 10-4 × [ ( TS × V ) / R ] |

| I-HP = 2.2 × 10-4 × [ ( 10675 × 10 ) / 66.5] = 0.32 ( HP ) | |

| Ngokubanzi, amandla omatshini wokuhambisa umbane angaphulukana ne-11% ngexesha lokusebenza. | |

| MHP = [ 0.32 / (100 - 11 ) ]× 100 = 0.35 ( HP ) | |

| Ukwamkela i-1/2HP drive motor lukhetho olufanelekileyo. |

Sidwelisa imizekelo esebenzayo kwesi sahluko kwireferensi yakho, kwaye sikukhokele ukuba ubalele uvavanyo kunye nokuqinisekisa iziphumo zokubala.

Umhambisi oqhutywa kwiziko

I-conveyor eqokelelweyo ihlala isetyenziswa kwishishini lesiselo.Uyilo lomqhubi yi-2M ububanzi kunye ne-6M ubude besakhelo esipheleleyo.Isantya sokusebenza somthumeli sikwi-20M/min;iqala kwimeko yeemveliso eziqokelelana kwibhanti kwaye isebenze kwindawo eyomileyo eyi-30℃.Ukulayishwa kwebhanti yi-80Kg / m2 kunye neemveliso zokuthutha iikhenki ze-aluminium kunye nesiselo ngaphakathi.I-wearstrips yenziwe ngezinto ze-UHMW, kwaye yamkelwe i-Series 100BIP, i-sprocket yensimbi engenasici enamazinyo angama-10, kunye ne-stainless steel drive / i-idler shaft kwi-50mm x 50mm ubukhulu.Iifomula zokubala ezifanelekileyo zezi zilandelayo.

-

Ukunyuka kokuhanjiswa - Wf

| IFOMU : | Wf = WP × FBP × PP |

| Wf = 80 × 0.4 × 1 = 32 ( Kg / M ) |

-

Ukubalwa koxinzelelo lwethiyori yeyunithi - TB

| IFOMU : | TB =〔 ( WP + 2 WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔 ( 100 + ( 2 × 8.6 ) × 0.12 + 32 〕× 6 + 0 = 276.4 (kg / M) |

-

Ukubalwa kweyunithi yoxinzelelo lulonke- TW

| IFOMU : | TW = TB × FA |

| TW = 276.4 × 1.6 = 442 ( Kg / M ) | |

| TWS = 2 TW = 884 Kg / M | |

| I-TWS yayo ingundoqo wokuqhuba |

-

Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

| TA = 1445 × 1.0 × 0.95 = 1372 ( Kg / M ) | |

| Ngenxa yexabiso le-TA likhulu kune-TW, Ngoko ke, ukwamkela nge-HS-100 kukhetho olufanelekileyo. |

-

Nceda ubhekisele kwisithuba seSprocket se-HS-100 kwiSahluko se-Drive Sprockets;isithuba esikhulu se-sprocket simalunga ne-120mm kolu yilo.

-

I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TW + SW ) × BW |

| SL = ( 884 + 19.87 ) × 2 = 1807 ( Kg ) | |

| DS = 5 × 10-4 [ ( SL × SB3 ) / ( E × I )] | |

| DS = 5 × 10-4 × [ ( 1791 × 21003 ) / ( 19700 × 1352750 )] = 0.3 mm | |

| Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo. |

-

Ukubalwa kwe-shaft torque - TS

| IFOMU : | TS = TWS × BW × R |

| TS = 884 × 2 × 97 = 171496 ( kg - mm) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi yokuKhethwa kweShaft, siyazi ukuba ukusetyenziswa kwe-50mm × 50mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

-

Ukubalwa kwamandla eHashe - HP

| IFOMU : | I-HP = 2.2 × 10-4 [ ( TS × V ) / R ] |

| HP =2.2 × 10-4 × [ ( 171496 × 4 ) / 82] = 1.84 ( HP ) | |

| Ngokubanzi, amandla omatshini wokujika anokuphulukana ne-25% ngexesha lokusebenza. | |

| MHP = [ 1.84 / ( 100 - 25 )] × 100 = 2.45 ( HP ) | |

| Ukwamkela i-3HP drive motor lukhetho olufanelekileyo. |

Cofa kwiConveyor

I-incline conveyor system ibonisa kulo mfanekiso ungasentla yenzelwe ukuhlamba imifuno.Ubude bayo obuthe nkqo yi-4M, ubude obupheleleyo bomthumeli yi-10M, kunye nobubanzi bebhanti yi-900mm.Isebenza kwindawo yomswakama kunye nesantya se-20M / min ukuthutha ii-peas kwi-60Kg / M2.I-wearstrips yenziwe ngezinto ze-UHMW, kwaye ibhanti lokuhambisa yi-HS-200B kunye ne-50mm (H) iindiza kunye ne-60mm (H) yabalindi becala.Inkqubo iqala kwimeko ngaphandle kokuthwala iimveliso, kwaye igcina ukusebenza ubuncinane kwiiyure ze-7.5.Ikwamkele kunye ne-sprockets enamazinyo ali-12 kunye nentsimbi engatyiwa 38mm x 38mm drive/idler shaft.Iifomula zokubala ezifanelekileyo zezi zilandelayo.

- Ukubalwa koxinzelelo lwethiyori yeyunithi - TB

| IFOMU : | TB =〔( WP + 2WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔( 60 + ( 2 × 4.4 ) × 0.12 + 0 ) 〕× 10 + ( 60 × 4 ) = 322.6 ( kg / M ) | |

| Ngenxa yoko ayikokuqokelelwa kokuhanjiswa,Wf inokungahoywa. |

- Ukubalwa kweyunithi yoxinzelelo lulonke - TW

| IFOMU : | TW = TB × FA |

| TW = 322.6 × 1.6 = 516.2 ( Kg / M ) |

- Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

| TA = 980 × 1.0 × 0.95 = 931 | |

| Ngenxa yexabiso i-TA inkulu kune-TW;ngoko ke, ukwamkela ibhanti lokuhambisa iHS-200BFP lukhetho olukhuselekileyo nolufanelekileyo. |

- Nceda ubhekisele kwisithuba seSprocket se-HS-200 kwiSahluko se-Drive Sprockets;isithuba esikhulu se-sprocket simalunga nama-85mm kolu yilo.

- I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TW + SW ) × BW |

| SL = ( 516.2 + 11.48 ) × 0.9 = 475 Kg | |

| IFOMU : | DS = 5 × 10-4 × [ ( SL x SB3 ) / ( E x I )] |

| DS = 5 × 10-4 × [ ( 475 × 10003 ) / ( 19700 × 174817 )] = 0.069 mm | |

| Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo. |

- Ukubalwa kwe-shaft torque - TS

| IFOMU : | TS = TW × BW × R |

| TS = 322.6 × 0.9 × 49 = 14227 ( kg - mm) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi ye-Shaft Selection, siyazi ukuba ukusetyenziswa kwe-38mm × 38mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

- Ukubalwa kwamandla eHashe - HP

| IFOMU : | HP = 2.2 × 10-4 × [ ( TS × V ) / R ] |

| I-HP = 2.2 × 10-4 × [ ( 14227 × 20 ) / 49] = 1.28 ( HP ) | |

| Ngokubanzi, amandla omatshini wokujika anokuphulukana ne-20% ngexesha lokusebenza. | |

| MHP = [ 1.28 / ( 100 - 20 )] × 100 = 1.6 ( HP ) | |

| Ukwamkela i-2HP drive motor lukhetho olufanelekileyo. |

Ukuguqula iConveyor

Inkqubo yokuhambisa i-conveyor kumfanekiso ongentla yi-90 degree converting conveyor. I-wearstrips kwindlela yokubuyisela kunye nendlela yokuthwala zombini zenziwe ngezinto ze-HDPE.Ububanzi bebhanti yokuhambisa yi-500mm;ithatha ibhanti le-HS-500B kunye ne-sprockets enamazinyo angama-24.Ubude becandelo elisebenzayo elithe ngqo yi-2M ekupheleni kwe-idler kunye ne-2M ekupheleni kwe-drive.Iradiyasi yayo yangaphakathi yi-1200mm.I-friction factor ye-wearstrips kunye nebhanti yi-0.15.Izinto zokuthutha ziibhokisi zeebhokisi ezikwi-60Kg/M2.Isantya sokusebenza komthumeli yi-4M/min, kwaye sisebenza kwindawo eyomileyo.Ubalo olunxulumeneyo lulandelayo.

-

Ukubalwa kweyunithi yoxinzelelo lulonke - TWS

| IFOMU : | TWS = ( TN ) |

| Uxinzelelo olupheleleyo lwecandelo lokuqhuba kwindlela yokuthwala. | |

| T0 = 0 | |

| T1 = WB + FBW × LR × WB | |

| T1 = 5.9 + 0.35 × 2 × ( 5.9) = 10.1 | |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Uxinzelelo lwecandelo lokujika kwindlela yokubuya.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc. | |

| T2 = ( Ca × T2-1 ) + ( Cb × FBW × RO ) × WB | |

| TN = ( Ca × T1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( 1.27 × 10.1 ) + ( 0.15 × 0.35 × 1.7 ) × 5.9 = 13.35 | |

| IFOMU : | TN = TN-1 + FBW × LR × WB |

| Uxinzelelo lwecandelo elithe tye kwindlela yokubuya. | |

| T3 = T3-1 + FBW × LR × WB | |

| T3 = T2 + FBW × LR × WB | |

| T3 = 13.35 + 0.35 × 2 × 5.9 = 17.5 | |

| IFOMU : | TN = TN-1 + FBW × LP × ( WB + WP ) |

| T4 = T4-1 + FBW × LP × ( WB + WP ) | |

| T4 = T3 + FBW × LP × ( WB + WP ) | |

| T4 = 17.5 + 0.35 × 2 × ( 5.9 + 60 ) = 63.6 | |

| Uxinzelelo lwecandelo elithe tye kwindlela yokuthwala. | |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Uxinzelelo lwecandelo lokujika kwindlela yokubuya.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc. | |

| T5 = ( Ca × T5-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T5 = ( Ca × T6 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T5 = ( 1.27 × 63.6 ) + ( 0.15 × 0.35 × 1.7 ) × ( 5.9 + 60 ) = 86.7 |

-

Iyonke ingcinezelo yebhanti TWS (T6)

| IFOMU : | TWS = T6 = TN-1 + FBW × LP × ( WB + WP ) |

| Uxinzelelo olupheleleyo lwecandelo elithe tye kwindlela yokuthwala. | |

|

| T6 = T6-1 + FBW × LP × ( WB + WP ) |

|

| T6 = T5 + FBW × LP × ( WB + WP ) |

|

| T6 = 86.7 + 0.35 × 2 × ( 5.9 + 60 ) = 132.8 ( Kg / M ) |

|

|

|

-

Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

|

| TA = 2118 × 1.0 × 0.95 = 2012 ( Kg / M ) |

|

| Ngenxa yexabiso i-TA inkulu kune-TW;ngoko ke, ukwamkela Series 500B ibhanti lokuhambisa kukhetho olukhuselekileyo nolufanelekileyo. |

-

Nceda ubhekisele kwisithuba seSprocket se-HS-500 kwiSahluko se-Drive Sprockets;isithuba esikhulu se-sprocket simalunga ne-145mm.

-

I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TWS + SW ) ×BW |

| SL = ( 132.8 + 11.48 ) × 0.5 = 72.14 ( Kg ) | |

| IFOMU : | DS = 5 × 10-4 × [ ( SL × SB3 ) / ( E × I )] |

| DS = 5 × 10-4 × [ ( 72.14 × 6003 ) / ( 19700 × 174817 )] = 0.002 ( mm) | |

| Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo. |

-

Ukubalwa kwe-shaft torque - TS

| IFOMU : | TS = TWS × BW × R |

| TS = 132.8 × 0.5 × 92.5 = 6142 (kg - mm) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi yokuKhethwa kweShaft, siyazi ukuba ukusetyenziswa kwe-50mm × 50mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

-

Ukubalwa kwamandla eHashe - HP

| IFOMU : | HP = 2.2 × 10-4 × [ ( TS × V / R )] |

| I-HP = 2.2 × 10-4 × [ ( 6142 × 4 ) / 95] = 0.057 ( HP ) | |

| Ngokubanzi, amandla omatshini wokujika anokuphulukana ne-30% ngexesha lokusebenza. | |

| MHP = [ 0.057 / ( 100 - 30 )] × 100 = 0.08 ( HP ) | |

| Ukwamkela i-1/4HP drive motor lukhetho olufanelekileyo. |

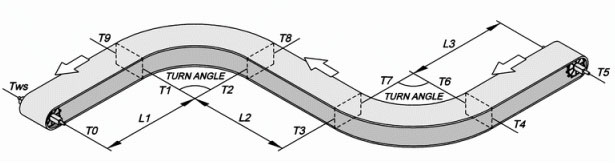

Uthotho Turning Conveyor

Isixokelelwano sokuhambisa esijikelezayo sakhiwe ngabahambisi ababini be-90 degree kunye necala elichaseneyo.I-wearstrips ngendlela yokubuyisela kunye nendlela yokuthwala zombini zenziwe ngezinto ze-HDPE.Ububanzi bebhanti yokuhambisa yi-300mm;ithatha ibhanti le-HS-300B kunye ne-sprockets enamazinyo ayi-12.Ubude becandelo elisebenzayo elichanekileyo li-2M ekupheleni kwe-idler, i-600mm kwindawo yokudibanisa, kunye ne-2M ekupheleni kwe-drive.I-radius yayo yangaphakathi yi-750mm.I-friction factor ye-wearstrips kunye nebhanti yi-0.15.Izinto zokuthutha ziibhokisi zeplastiki kwi-40Kg/M2.Isantya sokusebenza komthumeli si-5M/min, kwaye sisebenza kwindawo eyomileyo.Ubalo olunxulumeneyo lulandelayo.

-

Ukubalwa kweyunithi yoxinzelelo lulonke - TWS

| IFOMU : | TWS = ( TN ) |

|

| T0 = 0 |

| Uxinzelelo olupheleleyo lwecandelo lokuqhuba kwindlela yokuthwala. | |

|

| T1 = WB + FBW × LR × WB |

|

| T1 = 5.9 + 0.35 × 2 × 5.9 = 10.1 |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Uxinzelelo lwecandelo lokujika kwindlela yokubuya.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc. | |

| T2 = ( Ca × T2-1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( Ca × T1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( 1.27 × 10.1) + ( 0.15 × 0.35 × 1.05 ) × 5.9 = 13.15 | |

| IFOMU : | TN = TN-1 + FBW × LR × WB |

| Uxinzelelo lwecandelo elithe tye kwindlela yokubuya. | |

| T3 = T3-1 + FBW × LR × WB | |

| T3 = T2 + FBW × LR × WB | |

| T3 = 13.15 + ( 0.35 × 0.6 × 5.9 ) = 14.3 | |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Uxinzelelo lwecandelo lokujika kwindlela yokubuya.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc. | |

| T4 = ( Ca × T4-1 ) + ( Cb × FBW × RO ) × WB | |

| TN = ( Ca × T3 ) + ( Cb × FBW × RO ) × WB | |

| T4 = ( 1.27 × 14.3 ) + ( 0.15 × 0.35 × 1.05 ) × 5.9 = 18.49 | |

| IFOMU : | TN = TN-1 + FBW × LR × WB |

| Uxinzelelo lwecandelo elithe tye kwindlela yokubuya. | |

| T5 = T5-1 + FBW × LR × WB | |

| T5 = T4 + FBW × LR × WB | |

| T5 = 18.49 + ( 0.35 × 2 × 5.9 ) = 22.6 | |

| IFOMU : | TN = TN-1 + FBW × LP × ( WB + WP ) |

| Uxinzelelo lwecandelo elithe tye kwindlela yokuthwala. | |

| T6 = T6-1 + FBW × LP × ( WB + WP ) | |

| T6 = T5 + FBW × LP × ( WB + WP ) | |

| T6 = 22.6 + [ ( 0.35 × 2 × ( 5.9 + 40 ) ] = 54.7 | |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Uxinzelelo lwecandelo lokujika kwindlela yokuthwala.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc | |

| T7 = ( Ca × T7-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T7 = ( Ca × T6 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T7 = ( 1.27 × 54.7 ) + ( 0.15 × 0.35 × 1.05 ) × ( 40 + 5.9 ) = 72 | |

| IFOMU : | TN = TN-1 + FBW × LP × ( WB + WP ) |

| Uxinzelelo lwecandelo elithe tye kwindlela yokuthwala. | |

| T8 = T8-1 + FBW × LP × ( WB + WP ) | |

| TN = T7 + FBW × LP × ( WB + WP ) | |

| T8 = 72 + [ ( 0.35 × 0.5 × ( 40 + 5.9 ) ] = 80 | |

| IFOMU : | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Uxinzelelo lwecandelo lokujika kwindlela yokuthwala.Ngexabiso le-Ca kunye ne-Cb, nceda ubhekisele kwiTheyibhile Fc | |

| T9 = ( Ca × T9-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T9 = ( Ca × T8 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T9 = ( 1.27 × 80 ) + ( 0.15 × 0.35 × 1.05 ) × ( 40 + 5.9 ) =104 |

- Iyonke ingcinezelo yebhanti TWS (T6)

| IFOMU : | TWS = T10 |

| Uxinzelelo olupheleleyo lwecandelo elithe tye kwindlela yokuthwala. | |

| TN = TN-1 + FBW × LP × ( WB + WP ) | |

| T10 = T10-1 + FBW × LP × ( WB + WP ) | |

| T10 = 104 + 0.35 × 2 × ( 5.9 + 40 ) = 136.13 ( Kg / M ) |

-

Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

| TA = 2118 × 1.0 × 0.95 = 2012 ( Kg / M ) | |

| Ngenxa yexabiso i-TA inkulu kune-TW;ngoko ke, ukwamkela Series 300B ibhanti lokuhambisa kukhetho olukhuselekileyo nolufanelekileyo. |

-

Nceda ubhekisele kwisithuba seSprocket kwiSahluko seDrive Sprockets;isithuba esikhulu se-sprocket simalunga ne-145mm.

-

I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TWS + SW ) × BW |

| SL = ( 136.13 + 11.48 ) × 0.3 = 44.28 ( Kg ) | |

| IFOMU : | DS = 5 × 10-4 × [ ( SL × SB3 ) / ( E x I )] |

| DS = 5 × 10-4 × [ ( 44.28 × 4003 ) / ( 19700 × 174817 ) = 0.000001 ( mm) | |

| Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo. |

-

Ukubalwa kwe-shaft torque - Ts

| IFOMU : | TS = TWS × BW × R |

| TS = 136.3 × 0.3 × 92.5 = 3782.3 ( kg - mm) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi ye-Shaft Selection, siyazi ukuba ukusetyenziswa kwe-38mm × 38mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

-

Calc, ulat, io, n of horsepower - HP

| IFOMU : | HP = 2.2 × 10-4 × [ ( TS × V ) / R ] |

| I-HP = 2.2 × 10-4 × [ ( 3782.3 × 5 ) / 92.5] = 0.045 ( HP ) | |

| Ngokubanzi, amandla omatshini we-center drive conveyor anokulahlekelwa malunga ne-30% ngexesha lokusebenza. | |

| MHP = [ 0.045 / ( 100 - 30 )] × 100 = 0.06 ( HP ) | |

| Ukwamkela i-1/4HP drive motor lukhetho olufanelekileyo. |

I-Spiral Conveyor

Imifanekiso ebonisa apha ngasentla ngumzekelo wenkqubo yokuhambisa ejikelezayo enamaleko amathathu.Iingubo zendlela yokuthwala kunye nendlela yokubuya zenziwe ngezinto ze-HDPE.Ububanzi bebhanti bubonke yi-500mm kwaye yamkele i-HS-300B-HD kunye ne-sprockets enamazinyo ayi-8.Ubude becandelo elithwele ngokuthe tye kwi-drive kunye ne-idler end yi-1 mitha ngokulandelanayo.I-radius yayo yangaphakathi yokujika yi-1.5M, kwaye izinto zokuthutha ziibhokisi zeposi kwi-50Kg/M2.Isantya sokusebenza somthumeli si-25M / min, sithambekele ekuphakameni kwe-4M kwaye sisebenze kwindawo eyomileyo.Ubalo olunxulumeneyo lulandelayo.

-

Ukubalwa kweyunithi yoxinzelelo lulonke - TWS

| IFOMU : | TW = TB × FA |

|

| TWS = 958.7 × 1.6 = 1533.9 ( Kg / M ) |

|

| |

| IFOMU : | TB = [ 2 × R0 × M + ( L1 + L2 ) ] ( WP + 2 WB ) × FBW + ( WP × H ) |

|

| I-TB = [ 2 × 3.1416 × 2 × 3 + ( 1 + 1 )] ( 50 + 2 × 5.9 ) × 0.35 + ( 50 × 2 ) |

| I-TB = 958.7 ( Kg / M ) |

- Ukubalwa kweyunithi yoxinzelelo oluvumelekileyo - TA

| IFOMU : | TA = BS × FS × FT |

| TA = 2118 × 1.0 × 0.95 = 2012 ( Kg / M ) | |

| Ngenxa yexabiso i-TA inkulu kune-TW;ngoko ke, ukwamkela Series 300B-HD ibhanti lukhetho olukhuselekileyo nolufanelekileyo. |

- Nceda ubhekisele kwisithuba seSprocket se-HS-300 kwiSahluko se-Drive Sprockets;isithuba esikhulu se-sprocket simalunga ne-145mm.

- I-Deflection ratio ye-drive shaft - i-DS

| IFOMU : | SL = ( TWS + SW ) × BW |

| SL = ( 1533.9 + 11.48 ) × 0.5 = 772.7 ( Kg ) | |

| IFOMU : | DS = 5 × 10-4 × [ ( SL × SB3 ) / ( E × I )] |

| DS = 5 × 10-4 × [ ( 772.7 × 6003 ) / ( 19700 × 174817 )] = 0.024 ( mm) |

- Ukuba isiphumo sobalo sincinci kunexabiso elisemgangathweni elidweliswe kwiTheyibhile yokuPhambuka;ukwamkela iibheringi ezimbini zebhola kwanele kwinkqubo.

- Ukubalwa kwe-shaft torque - TS

| IFOMU : | TS = TWS × BW × R |

| TS = 1533.9 × 0.5 × 92.5 = 70942.8 (kg - mm) | |

| Xa kuthelekiswa ne-Maximum Torque Factor kwiyunithi ye-Shaft Selection, siyazi ukuba ukusetyenziswa kwe-38mm × 38mm square shaft kukhuselekile kwaye kukhethwe ngokufanelekileyo. |

- Ukubalwa kwamandla ehashe - HP

| IFOMU : | HP = 2.2 × 10-4 × [ ( TS × V ) / R ] |

| I-HP = 2.2 × 10-4 × [ ( 70942.8 × 4 ) / 60 = 1.04 ( HP ) | |

| Ngokubanzi, amandla omatshini we-center drive conveyor anokulahlekelwa malunga ne-40% ngexesha lokusebenza. | |

| MHP = [ 1.04 / ( 100 - 40 )] × 100 = 1.73 ( HP ) | |

| Ukwamkela i-2HP drive motor lukhetho olufanelekileyo. |