Khangela kuqala

Hlola ibhanti kwiimeko ezingaqhelekanga okanye unxibe umonakalo ngaphambi kokuba uqale.

Hlola kwaye uqinisekise ukuba i-catenary sag yomzantsi webhanti ikwindawo efanelekileyo.

Ukuba umhambisi wamkela uhlengahlengiso loxinzelelo, lujonge kwaye uqinisekise ukuba ukutsalwa kwebhanti akuqiniswanga kakhulu.Musa ukudlula amandla ibhanti elinokunyamezela, ngaphandle kohlobo olutyhalweyo lokuhambisa.

Jonga zonke iiroli ezixhasayo kwaye uqinisekise ukuba zikwimeko entle ejikelezayo.

Jonga i-drive/idler sprocket ukonakaliswa okugqithisileyo

Jonga indawo yokudityaniswa phakathi kwesprockets kunye nebhanti yokususa zonke izinto ebezincamathele ngaphakathi.

Qwalasela zonke iintambo zokunxiba kwaye ubambe iireyile kuwo nawuphi na umonakalo ongaqhelekanga okanye ogqithisileyo.

Jonga zombini i-drive kunye ne-idler shafts, kwaye uqiniseke ukuba zidityanisiwe kunye nebhanti yokuhambisa.

Qwalasela zonke izithuba ebezifuneka ukuba zithanjiswe kwaye uqinisekise ukuba zikwimeko eqhelekileyo.

Qwalasela zonke iindawo ebezifuneka ukuze zicocwe kwisixokelelwano sokuhambisa.

Ukucoca Ukubaluleka

Xa uhlambulula ibhanti, kuyimfuneko ukuphepha ukusebenzisa i-detergent equkethe izithako ezinobungozi.

Nangona iyasebenza kwaye iluncedo ukusebenzisa i-detergent yokuhlamba ukungcola;nangona kunjalo, inokuba nefuthe kwizinto zeplastiki zebhanti kwaye icuthe ixesha elide lokusebenzisa ibhanti.

Iimveliso ze-serial ze-HONGSBELT zebhanti zokuthutha ziyilwe ngokusisiseko ngokucoca lula kunye neempawu zokuhambisa amanzi;ngoko ke, yeyona ndlela ifanelekileyo yokucoca amabhanti ngamanzi oxinzelelo oluphezulu okanye umoya oxinanisiweyo.

Ngaphandle koko, kuyimfuneko ukucoca ukungcola kunye nezinye izinto eziqhekezayo ukusuka ngaphantsi okanye inxalenye yangaphakathi yomqhubi.Nceda uqinisekise ukuba umatshini uvala umbane ukunqanda nayiphi na ingozi enokwenzeka.Kwezinye izicelo zokwenza ukutya, kukho umgubo wesoggy, isiraphu okanye ezinye izinto ezishiyekileyo eziwela kwisixokelelwano sokuhambisa kwaye zikhokelela kungcoliseko lomhambisi.

Ezinye izinto ezingcolisayo ezinjengothuli, igrabile, isanti okanye i-cullet zinokuchaphazela inkqubo yokuhambisa ukudibana neengxaki ezinzulu.Ke ngoko, ukucocwa kwesiqhelo okanye ngamaxesha athile kwisixokelelwano sokuhambisa ngumsebenzi oyimfuneko wokugcina isixhobo sikwimeko eqhelekileyo.

Isondlo

Uvavanyo lwesiqhelo okanye lovavanyo lwamaxesha athile lwe-conveyor ikakhulu kukuthintela iingxaki ezingaqhelekanga, kwaye kukunceda ugcine umhambisi ngaphambi kokuba iimeko zokusilela zenzeke.Ngokubanzi, abasebenzisi banokujonga imeko yokunxiba ngokuhlolwa okubonakalayo, kwaye bathathe isigqibo sokuba ngaba kuyimfuneko na ukuqhubeka nako nakuphi na ukulungiswa okanye ukutshintshwa okanye hayi.Nceda ujonge ku-Nkathazo Shooting kwimenyu esekhohlo ukulungiselela ulungiso kunye nenjongo yokutshintsha.

Ibhanti yokuhambisa inobomi obuthile phantsi kokusetyenziswa rhoqo;Iwaranti yeebhanti zokuhambisa ze-HONGSBELT ziinyanga ezili-12.Emva kokusetyenziswa ixesha elide, ibhanti liya kuguga, lijikwe ngenxa yokugcwala, okanye kwandiswe isithuba.Kuzo zonke izizathu ezikhankanywe ngasentla ziya kubangela ukubandakanyeka okungalunganga phakathi kwebhanti kunye ne-sprockets.Kuyimfuneko ukugcina okanye ukubuyisela ibhanti ngelo xesha.

Ngexesha lokusebenza komthumeli, ibhanti lokuhambisa, iingubo zokunxiba kunye ne-sprockets ziya kunxiba ngokuzenzekelayo.Ukuba kukho nayiphi na imeko ye-abrasion yebhanti yokuhambisa, sincoma ukuba sitshintshe kunye nezixhobo ezintsha zebhanti, ukuze kugcinwe umqhubi osebenza kwiimeko eziqhelekileyo.

Ngokuqhelekileyo, xa umhambisi kufuneka atshintshe ibhanti elitsha, ii-wearstrips kunye ne-sprockets zicetyiswa ngamandla ukuba zihlaziye ngexesha elifanayo.Ukuba siyayihoya enye yazo, inokunyusa ukonakala kwebhanti kunye nokunciphisa ixesha lokuphila kwebhanti kunye nezixhobo.

Ubukhulu becala ibhanti lokuhambisa le-HONGSBELT lifuna kuphela ukubuyisela iimodyuli zebhanti ezintsha kunye nesikhundla somonakalo, akufuneki ukutshintsha ibhanti lonke.Ukuqhaqha nje inxalenye eyonakalisiweyo yebhanti, kwaye ubeke iimodyuli ezintsha, kwaye umthumeli unokubuyela ekusebenzeni ngokulula.

Ukhuseleko & Isilumkiso

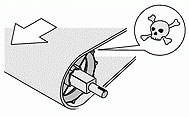

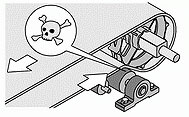

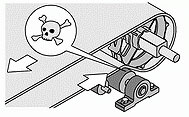

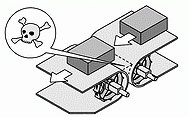

Xa ibhanti lokuhambisa lisebenza, kukho iindawo ezininzi ezinobungozi ekufuneka abasebenzi, abasebenzisi kunye nabasebenzi bolondolozo banike ingqwalasela.Ngokukodwa icandelo eliqhutywayo le-conveyor, inokubamba okanye yenzakalise umzimba womntu;ke ngoko, wonke umntu kufuneka abe noqeqesho olufanelekileyo kunye nemfundo yokuhambisa izithuthi ezisebenza kwangaphambili.Kukwayimfuneko ukulebhelisha izilumkiso ezinobungozi kunye nesalathiso kwindawo yengozi ngombala okhethekileyo okanye iimpawu ezilumkisayo, ukuze kuthintelwe umngcipheko ongengozi ngexesha lokusebenza komthumeli.

Isalathiso seNdawo enobungozi

▼ Indawo eqhuba isprocket edibene nebhanti.

▼ Indawo ebuyisela indlela yokunxibelelana nebhanti.

▼ Indawo apho i-Idler idibene nebhanti.

▼ Umsantsa wendawo yokudluliselwa phakathi kwabahambisi.

▼ Isithuba phakathi kwabahambisi ngerola yodluliselo.

▼ Isithuba phakathi kwabahambisi ngepleyiti efileyo.

▼ Indawo apho ibhanti lidibene khona nothintelo lwecala.

▼ Indawo yeRadius engasemva kwindlela yokuthwala.

▼ Indawo yeradiyasi yangasemva kwindlela yokubuyisela.

▼ Indawo yongqameko lwebhanti edityaniswe nesakhelo.

Ukuqhawuka kwamaBhanti

| Isizathu | Indlela yokuSombulula |

| Ukungaphumeleli kombane ngexesha lokuthwala isixa esikhulu seemveliso, ngelixa umbane ubuyela umva, umqhubi uya kuqalisa ngokukhawuleza ngokulayisha okugcweleyo, utsalo oluluqilima loxinzelelo loxinzelelo lubangela ukuqhawuka kwebhanti lokuhambisa. | Susa iimveliso zokuthwala kwibhanti kwaye ubuyisele iimodyuli ezintsha kwindawo eyaphukileyo, emva koko uqalise inkqubo kwakhona. |

| Izithintelo zisekwe phakathi kwesakhelo sokuhambisa kunye nebhanti, njengokukhulula isikrufu okanye izikhewu zokunxiba ezixhasayo.Oku kunokubangela imeko yokulayisha ngaphezulu kwaye bonakalise ibhanti lokuhambisa. | Ukuphelisa izithintelo kunye nokulungelelanisa isithuba soqhagamshelwano phakathi kwesakhelo sokuhambisa kunye nebhanti. |

| I-backbend radius position ibanjwe zizinto zangaphandle kwisithuba phakathi kweemodyuli zebhanti zeplastiki. | Nceda ubhekisele kwi-Backbend Radius kwi-Incline okanye ye-Decline Design Chapter. |

| Ukuphambuka kwebhanti ebalekayo kubangela uthintelo lokonakalisa, njengempembelelo engaqhelekanga okanye ukudibana nezikrufu zokuqinisa kwisakhelo somatshini. | Qwalasela isakhelo somatshini ngokupheleleyo , kwaye uvavanye nayiphi na imeko yokudamba engaqhelekanga , ngakumbi kwezo zikrufu ziqhoboshelweyo. |

| Ii-rodlets ziyawa kumngxunya wokutshixa, zikhokele iintonga zehenjisi ziphuma kumda webhanti lokuhambisa kwaye zixinzelele ngaphakathi kwisakhelo somzimba womatshini. | Buyisela iimodyuli zebhanti zokuthutha ezonakalisiweyo, iintonga zehinge kunye neentonga zokutshixa.kwaye ujonge yonke imeko engaqhelekanga ngononophelo. |

| I-engile yerediyasi yangasemva icuthene kakhulu ekhokelela kumonakalo ngenxa yoxinzelelo lokuvaleka. | Nceda ubhekisele kwi-Backbend Radius kwi-Incline okanye ye-Decline Design Chapter |

Uthethathethwano olubi

Nxiba

| Isizathu | Indlela yokuSombulula |

| Kukho uphambuko lwe-engile yesakhelo sokuhambisa. | Lungisa ubume bomhambisi. |

| Ii-Wearstrip azifaki ukuhambelana nesakhelo sokuhambisa. | Lungisa ubume bomhambisi. |

| Akukho sikhewu sifanelekileyo esibekelwe ububanzi bebhanti kunye nesakhelo esisecaleni somhambisi | Nceda ujonge kuMda weSiseko kwisahluko seNgcaciso yoYilo. |

| Imekobume yokusebenza yokuhambisa inotshintsho olukhulu lobushushu ekwandeni kwe-thermal kunye nokucutheka. | Nceda ujonge kwiSahluko soKwandiswa kweNgcaciso yoYilo. |

| I-sprocket yaseziko ayitshixekanga ngokuchanekileyo kwindawo esembindini yedrive / idler shaft yokuhambisa | Hlukanisa i-sprocket kwi-shaft kwaye uyibuyisele kwindawo echanekileyo ye-shaft. |

| Umgca ophakathi othe ngqo webhanti lokuhambisa awudibanisi kakuhle nesprocket eseziko. | Lungisa ubume bomhambisi ukulungiselela uthethathethwano olufanelekileyo. |

Isandi esingaqhelekanga

| Isizathu | Indlela yokuSombulula |

| I-deformation ye-conveyor structure ibangela ukuba i-hub ye-sprocket ingakwazi ukubandakanya ngokufanelekileyo kunye nesithuba se-taper phantsi kobuso bebhanti yokuhambisa. | Lungisa i-drive / Idler shaft kwi-90 degree kwisakhelo sokuhambisa. |

| Kwibhanti yokuhambisa entsha kraca, kukho iibhutsi eziseleyo kwiimodyuli zeplastiki emva kokwenziwa kwenaliti. | Oku akuyi kuba nefuthe ekusebenzeni kwebhanti, i-burrs iya kunyamalala emva kokusebenza ixesha elide. |

| I-Sprockets kunye nebhanti yokuhambisa i-attrition egqithisileyo okanye ibhanti ngokwayo i-attrition egqithisileyo. | Faka esikhundleni iisprockets ezintsha okanye ibhanti elitsha lokuhambisa. |

| Isikhundla esixhasayo sebhanti yokuhambisa ayisebenzisi i-coefficient ephantsi yezinto eziphathekayo ukwenza i-spacers ezixhasayo. | Buyisela izikhewu ezixhasayo ezenziwe ngezinto zeplastiki kunye ne-coefficient ephantsi ye-friction. |

| Isakhelo sokuhambisa siyekele. | Jonga isakhelo sonke somhambisi kwaye uqhoboshele isikhonkwane ngasinye . |

| Ezinye izinto zinamathele kwi-gap edibeneyo yeemodyuli zifunyenwe. | Ukuphelisa ezinye izinto kwaye uhlambulule ibhanti. |

| Ngenxa yokuhluka kweqondo lokushisa, ibhanti lokuhambisa linotshintsho olukhulu ekwandiseni i-thermal kunye nokucutha. | Nceda ujonge kwiTemperature Rang ye-Belt Materials kwaye ukhethe ibhanti lokuhambisa elifanele ukusetyenziswa kuluhlu oluthile lobushushu. |

Thuthumela

| Isizathu | Indlela yokuSombulula |

| Isithuba phakathi kweeroli zendlela yokubuya zigqithise. | Ukulungelelanisa isithuba esifanelekileyo phakathi kweerola, nceda ujonge kwiCatenary Sag Table kuBude bebhanti kunye nesahluko soxinzelelo. |

| Igophe eligqithileyo le-catenary sag ngendlela eyimbuyekezo inokubangela ukuba i-engile yoqhagamshelwano phakathi kwe-catenary sag position kunye ne-return way rollers zibe nkulu.Oko kuya kubangela intshukumo yepitch yebhanti, kwaye i-idler sprocket ayinakukwazi ukufunxa indlela ebuyayo yoxinzelelo kakuhle.Ibhanti iya kusebenza kwimeko engcangcazelayo. | Ukulungelelanisa isithuba esifanelekileyo phakathi kweerola, nceda ujonge kwiCatenary Sag Table kwi-InclLength & Tension chapter. |

| Ukudibanisa okungafanelekanga kweentambo zokunxiba kunye nokubamba iileyili kuya kuba nefuthe ekusebenzeni kwebhanti. | Lungisa okanye lungisa kwakhona iileyili zokubamba.Iireyili ekungeneni kwebhanti zifuna ukusetyenzwa zibe ngunxantathu oguquliweyo. |

| Kukho ukuhla okugqithisileyo kwi-engile yendawo edibeneyo phakathi kwe-drive / idler shaft kunye nesikhundla sokuxhasa. | Nceda ujonge kuMda weSiseko kwisahluko seNgcaciso yoYilo. |

| Umqolo weradiyasi webhanti awulandeli ubuncinci bomda weradiyasi o uyilo. | Nceda ubhekisele kwi-Backbend Radius Ds kwi-Clide okanye ye-Decline Design isahluko. |

| I-diameter ye-return way rollers okanye i-wearstrips incinci kakhulu;bekuya kubangela ukuguqulwa kwempahla yokunxiba. | Nceda ubhekisele kwiReturn Way Rollers kwisahluko seNkxaso yeReturn. |

| Indlela ebuya ngayo i-tension yebhanti ayihambelani ngokupheleleyo ne-Cap way tension yebhanti . | Lungisa uxinzelelo ngokufanelekileyo, lunokunyusa okanye lunciphise ubude bebhanti yokuhambisa. |

| Ibhanti lokuhambisa le-EASECON ligqithise ngaphakathi kwiradiyasi. | Lungisa ukucinezeleka kwebhanti lokuhambisa kakuhle njengoko kukhankanyiwe ngasentla, okanye buyisela ngokuthe ngqo iileyili zokubamba ngemathiriyeli ekwi-coefficient ephantsi yokukhuhlane njengeTeflon okanye iPolyacetal.Ukusebenzisa isepha yolwelo okanye i-lubricant kumphetho ongaphakathi wokubamba iileyili, iintambo eziphezulu zokunxiba kunye nenqanaba elisezantsi nazo ziyafumaneka.Le ndlela inokuba luncedo ekucombululeni ingxaki. |

Amanxeba angaphezulu

| Isizathu | Indlela yokuSombulula |

| Ukusika ngobunono umsebenzi weblade kushiye amanxeba anzulu kumphezulu webhanti. | Sandpaper umphezulu ibhanti agudileyo.Ukuba isakhiwo sebhanti sinomonakalo omkhulu, nceda utshintshe indawo eyonakalisiweyo ngeemodyuli ezintsha. |

IQF

| Isizathu | Indlela yokuSombulula |

| Ukusebenza kweempazamo kuqaliso lokuhambisa inkqubo yoMntu engumkhenkce ekhawulezileyo, kwaye iimodyuli zebhanti zibambekile bubushushu obuqhaqhazelisa amazinyo, zinokukhokelela kuxinzelelo olumandla xa inkqubo iqalwa;iphakame ngokugqithisileyo kunamandla okuzibamba ibhanti lokuhambisa elinokunyamezela. | Qinisekisa ukuba inkqubo iqalisa ngenkqubo echanekileyo, kwaye ubuyisele iimodyuli ezintsha kwindawo eyaphukileyo;emva koko uqalise umthumeli ngokwenkqubo echanekileyo.Nceda ubhekisele kuBubushushu obuphantsi kwindlela yeNkxaso yeSahluko. |

| Ubude bebhanti bufutshane kakhulu, kwaye buya kugqabhuka ngenxa yokwandiswa kwe-thermal kunye nokunciphisa. | Nceda ubhekisele kwiSahluko soKwandiswa kweNgcaciso yoYilo, ukubala ubude bebhanti obuchanekileyo obufunekayo. |

| Indawo ebanzi yoqhagamshelwano phakathi kweempahla zokunxiba kunye nebhanti lokuhambisa liya kubangela ukufumba komkhenkce. | Khetha i-wearstrips encinci ukunciphisa indawo yoqhagamshelwano, nceda ubhekisele kuBubushushu obuphantsi kwiSahluko seNdlela yeNkxaso. |

| Ukwahluka okukhulu kobushushu bokwandiswa kwe-thermal kunye nokucutheka kuya kubangela ukonakala kwesakhelo sokuhambisa kunye nokujijwa. | Ngexesha lokwenziwa kwe-conveyor edibeneyo, iyunithi yokudibanisa yefreyimu yobude kufuneka igcine ubuncinane i-1.5 M yomgama. |