Umsantsa odadayo

Xa uthatha ibhanti lokuhambisa kwintshukumo yokujika.Icandelo le-arc lokuhambisa liya kudibaniswa kunye nomqhubi othe tye kwaye iziphelo zombini zecandelo le-arc kufuneka zikhokelwe ngokuthe ngqo, kwaye emva koko umqhubi uya kusebenza kakuhle.

I-radius yangaphakathi ifuna ubuncinane amaxesha angama-2.2 ububanzi bebhanti yokuhambisa.

I-STL1 ≧ 1.5 XW okanye i-STL1 ≧ 1000mm

Ukujika okukodwa akupheleli kwi-90 °;kufuneka ithobele umda wokujika i-radius kwaye wenze uyilo ukusuka kwi-15 °, 30 °, 45 °, 60 °, 75 °, 90 °, .... ukuya kwi-360 °.

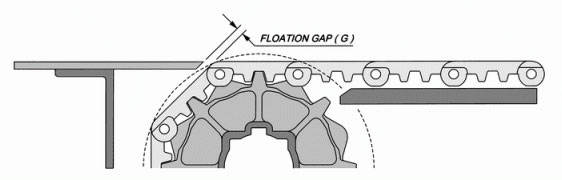

Itheyibhile yokuNgqogqa kweSikhewu esiDimensional Reference (G)

| iyunithi: mm | ||||

| Uthotho | Ukutyeba kweBhanti | Sprocket Diameter (PD) | Inani laMazinyo | Umsantsa odadayo ( G ) |

| 100 | 16 | 133 | 8 | 5.6 |

| 164 | 10 | 4.5 | ||

| 196 | 12 | 4.0 | ||

| 260 | 16 | 3.0 | ||

| 200 | 10 | 64 | 8 | 2.6 |

| 98 | 12 | 1.7 | ||

| 163 | 20 | 1 | ||

| 300 | 15 | 120 | 8 | 4.3 |

| 185 | 12 | 3.3 | ||

| 400 | 7 | 26 | 8 | 1 |

| 38.5 | 12 | 0.3 | ||

| 76.5 | 24 | 0 | ||

| 500 | 13 | 93 | 12 | 1.3 |

| 190 | 24 | 0.5 | ||

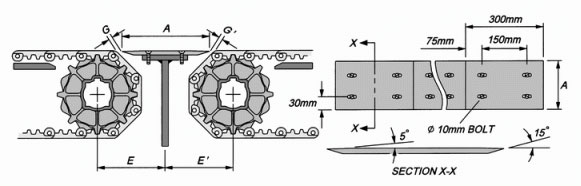

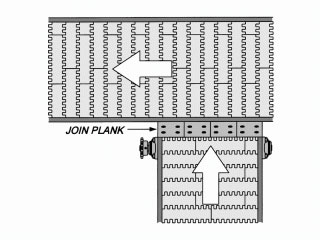

Icwecwe elifileyo

Sincoma ukuba uthathe ngaphezulu kwe-5mm engqindilili yentsimbi yekhabhoni, intsimbi engatyiwayo okanye ukuqina okuphezulu kwentsimbi yealloyi njl njl njengemathiriyeli yokwenza ipleyiti efileyo.Kubalulekile ukuqwalasela i-gap nganye yendawo yokudlulisa, ukwenza iimveliso zokulayisha zidlule kwindawo yokudlulisa kakuhle.

Nceda ubhekisele kuMdaniso oSisiseko kuLuhlu lweNgcaciso yoYilo ukuze ufumane ixabiso C, kwaye ubhekisele kwiGap edadayo kwesi sahluko ukuze ufumane ixabiso elingu-G, uze usebenzise le fomula ingezantsi, isiphumo sokubala siya kuba ngumlinganiselo wokwenyani womsantsa odadayo.

IFOMU:

E = CX 1.05

A = ( 2 XE ) ( G + G' )

Inkcazo yoyilo loTshintsho lwecala

Ngokubanzi, isicelo sokutshintshela isidanga se-90 sisetyenziswa ngendlela eqhelekileyo yenkqubo yokuhambisa.Sincoma ukuba uthathe i-HOMGSBELT ibhanti yokujika;inokukwenza ukuba usebenzise indawo ngokuguquguqukayo.

Ukuba indawo yefektri ayinkulu ngokwaneleyo kwi-radius encinci yokujika ye-HOMGSBELT ibhanti yokujika, kuyimfuneko ukwamkela uyilo lokudlulisa icala kwisakhelo ukusombulula le ngxaki.

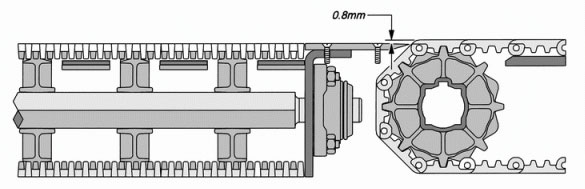

IiRola ezincedisayo

Kuyilo lwesikhundla sodluliselo phakathi kwabahambisi ababini, ukuba umzantsi weemveliso zokulayisha usicaba kwaye ubude bawo bungaphezulu kwe-150mm, ngaphandle kwepleyiti efileyo, inokusebenzisa i-roller encedisayo yokuhambisa ukuncedisa ibhanti lokuhambisa ukufumana ukuhanjiswa okugudileyo nokungcono. intshukumo ngexesha lokusebenza.

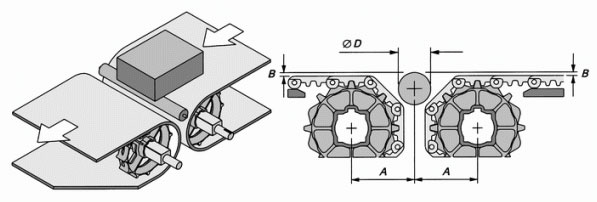

Ukucaciswa koYilo lweeRola eziNcedisayo zokuTshintshela kwi-Drive / Idler Position

| iyunithi: mm | ||||||

| Uthotho | Ukutyeba (Ibhanti) | Sprocket Dia. | Inani laMazinyo | A (imiz.) | B (imiz.) | D (ubuninzi.) |

| 100 | 16 | 133 | 8 | 85 | 0~1 | 34 |

| 164 | 10 | 100 | 40 | |||

| 196 | 12 | 116 | 50 | |||

| 260 | 16 | 150 | 66 | |||

| 200 | 10 | 64 | 8 | 47 | 20 | |

| 98 | 12 | 63 | 25 | |||

| 163 | 20 | 95 | 40 | |||

| 300 | 15 | 120 | 8 | 88 | 40 | |

| 185 | 12 | 106 | 44 | |||

| 400 | 7 | 26 | 8 | 20 | 10 | |

| 38.5 | 12 | 28 | 15 | |||

| 76.5 | 24 | 53 | 25 | |||

| 500 | 13 | 93 | 12 | 64 | 25 | |

| 190 | 24 | 118 | 40 | |||

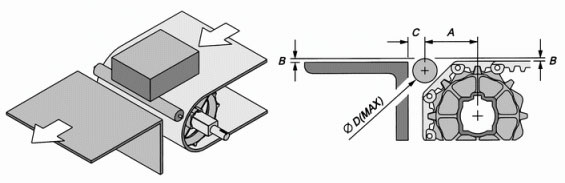

Inkcazo yoyilo lweeRola eziNcedisayo zokuTshintshela kwi-Platform Transfer

| Iyunithi: mm | |||||||

| Uthotho | Ukutyeba (Ibhanti) | Sprocket Dia. | Inani laMazinyo | A (imiz.) | B (imiz.) | C (imiz.) | D (ubuninzi.) |

| 100 | 16 | 133 | 8 | 74 | 0~1 | 23 | 20 |

| 164 | 10 | 92 | 28 | 25 | |||

| 196 | 12 | 106 | 33 | 30 | |||

| 260 | 16 | 138 | 41 | 38 | |||

| 200 | 10 | 64 | 8 | 42 | 18 | 15 | |

| 98 | 12 | 60 | 21 | 18 | |||

| 163 | 20 | 93 | 28 | 25 | |||

| 300 | 15 | 120 | 8 | 76 | 28 | 25 | |

| 185 | 12 | 108 | 30 | 27 | |||

| 400 | 7 | 26 | 8 | 17 | 9 | 6 | |

| 38.5 | 12 | 24 | 12 | 9 | |||

| 76.5 | 24 | 45 | 18 | 15 | |||

| 500 | 13 | 93 | 12 | 56 | 18 | 15 | |

| 190 | 24 | 108 | 28 | 25 | |||

Isixhobo sokukhokela

Xa iiplati ezifileyo okanye ii-rollers ezincedisayo zokudlulisa zisetyenziselwa indawo yokudluliselwa kwenkqubo yokuhambisa, ukuhlukana kwesantya somgca okanye i-centrifugal force, iimveliso ziya kuphoswa ngaphandle okanye ziphambuke kwindawo ephakathi kwebhanti.Okwangoku, kuyimfuneko ukufakela isixhobo sesikhokelo ukuncedisa iimveliso zidlula kwindawo yokuguqula kakuhle kwaye ngaphakathi kwendawo yokuthutha esebenzayo.

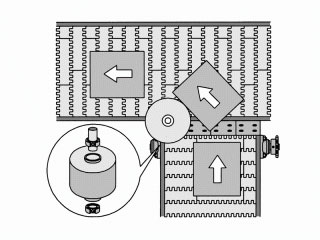

Inkcazo yoyilo lweRola yesiKhokelo

Ii-roller zesikhokelo ngokuqhelekileyo zenziwe ngezinto zetsimbi.I-radius yayo ekhokelayo imalunga ne-1/4 ububanzi obusebenzayo bebhanti.Ukuba iimveliso zokulayisha zifunwa ukunyusa ukukhuhlana, kufuneka ithathe irabha okanye i-PVC impahla yokugubungela umphezulu we-roller guide.Ilungele ngokukodwa ukulayisha okukhulu okanye okunzima kweemveliso zokuthutha.Ukusebenzisa iibhola zebhola kwi-roller yesikhokelo kunokukwenza ukuba i-roller ijikeleze ngakumbi.

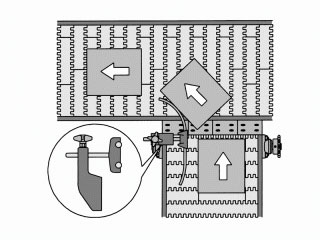

Inkcazo yoyilo lweSikhokelo sikaLoliwe

Uninzi lwezixhobo zesikhokelo zihlala zenziwe ngezinto zeplastiki ezinobunzima obuphantsi, njenge-UHMW, HDPE kunye nokunye.Isenokuyilwa ibeyimilo emininzi okanye imbonakalo yeemfuno zofakelo.Iireyile zesikhokelo zifanelekile ubungakanani obuphakathi okanye obuncinci bokulayisha kwesicelo sokuthutha.Iireyile zesikhokelo zenziwe ngezinto zeplastiki ezinobunzima obuphantsi.Abavelisi banokunikezela ngeentsimbi ezininzi zesikhokelo kuzo zonke iintlobo zeemilo kwiimfuno zabathengi.

Xa inkqubo yokuhambisa ithatha ipleyiti efileyo okanye ibherethi encedisayo ukusuka komnye umthuthi ukuya kwelinye kwi-angle ye-90 degree, ukudibanisa iirola zesikhokelo kunye neentsimbi zesikhokelo kuya kwenza inkqubo yokuthutha ibe lula kwaye ilula.

Nceda uqaphele ukuba ngaba iimveliso ziya kubetha umzila wesitimela wangaphandle ngenxa yamandla e-centrifugal xa ibhanti libaleka ukuya kwindawo yokujika, okanye ligqithise uluhlu olusebenzayo lwebhanti yokuthwala indlela kwaye ibangele iimveliso zifumba kwaye zidibanise umgca wemveliso.Ngokubanzi, ububanzi obusebenzayo bebhanti kufuneka bube bukhulu kunobubanzi obuphezulu bemveliso yokulayisha.