Indlela yeNkxaso

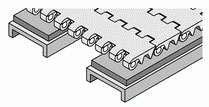

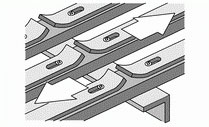

Eyona ndlela ixhasayo yebhanti yokuhambisa imodyuli ye-HONGSBELT ithatha i-wearstrips njengenkxaso phantsi kwebhanti.Ukuze ugweme ukwamkela i-rollers ukuxhasa ibhanti, kuba ukuhlukana phakathi kwee-roller kuya kubangela ukunyakaza okungaqhelekanga kwiimodyuli zokudibanisa isikhundla, kwaye i-sprockets iya kwenza ukubandakanyeka okungalunganga kunye nebhanti yokuhambisa.Zimbini iindlela eziqhelekileyo zokunxiba ezixhasayo;elinye lilungiselelo elihambelanayo kwaye elinye lilungiselelo le-chevron.Iibhanti zokuhambisa ze-HONGSBELT ziyakwazi ukuxhaswa kwiindlela zombini ezixhasayo.Imveliso ye-serial ye-HONGSBELT ifanelekile kwiindidi ezahlukeneyo zoyilo lwe-wearstrips.

ULungiselelo olunxuseneyo

Iingubo zokugqoka ezichanekileyo zifakwe kwisakhelo kwaye zihambelane nesikhokelo sokuthutha ibhanti.Lolona yilo ludumileyo lweemveliso ze-HONGSBELT ezamkelwayo.

Ingcaciso yoFakelo lwe-Parallel Wearstrip

Olona lungiselelo lulungileyo lwemicu yokunxiba kukunxibelelanisa imitya kunye nendlela enqamlezileyo esecaleni, ukunqanda isithuba sibe sikhulu ngenxa yokwanda kwe-thermal kunye nokucutheka okubangelwa kukutshintsha kobushushu.Ingadala isithuba kwimilo yegroove kwaye ibangele ingxolo kunye nokunqumama okungaqhelekanga ngenxa yebhanti lokuhambisa elizikayo ngexesha lokusebenza.

Ngokumalunga namalungiselelo esandi, nceda ujonge kwiPitch Diagram kwimenyu esekhohlo.

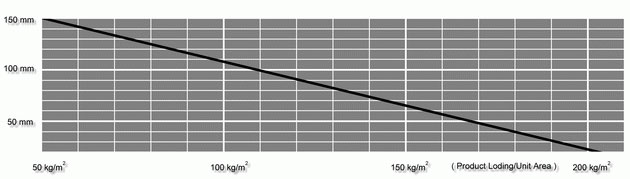

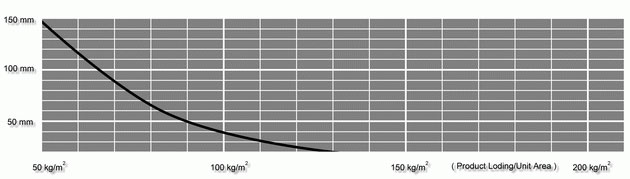

Umzobo wePitch-P of Series 100

Amanqaku

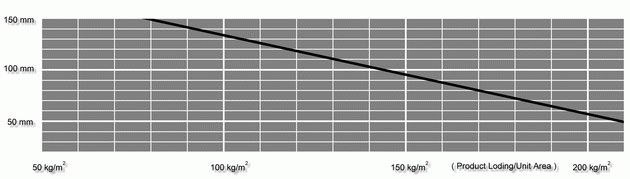

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

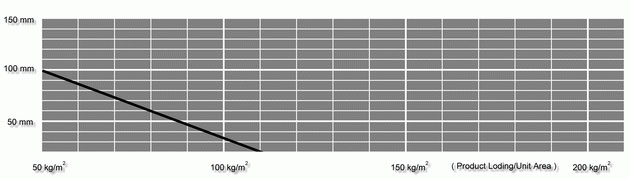

Umzobo wePitch-P of Series 200 Type A

Amanqaku

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

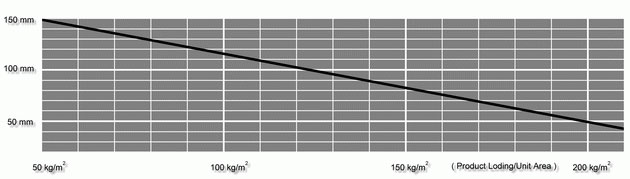

Itheyibhile yePitch Diagram - P yothotho lwama-200 Uhlobo B

Amanqaku

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

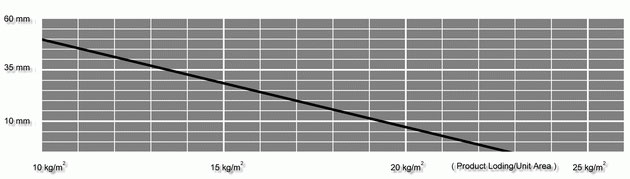

Itheyibhile yePitch Diagram-P yeSeries 300

Amanqaku

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

Umzobo wePitch-P of Series 400

Amanqaku

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

Umzobo wePitch-P of Series 500

Amanqaku

Igrafu engentla yidatha yezithuba zeziko elixhasa i-wearstrip;ezi datha luqikelelo kunye nereferensi kuphela.Nceda yabele i-avareji kwaye incinci kunedatha yegophe ngelixa uhlohla.

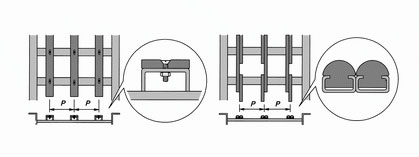

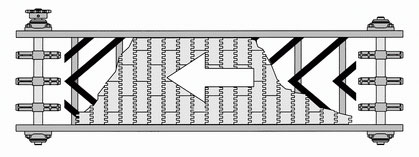

ULungiselelo lweChevron Wearstrips

Ukubeka i-wearstrips kwilungiselelo le-chevron;inokuxhasa ububanzi bonke bebhanti kunye nemeko yokunxiba yebhanti iya kusasazwa ngokulinganayo.Eli lungiselelo likwalungile kwizicelo zokulayisha kakhulu.Inokusasaza ukulayisha ngokulinganayo kunye nokunciphisa ububanzi obuxhasayo bebhanti;isiphumo sayo esikhokelayo kwintshukumo yerectilinear ikwangcono kuneentambo zokunxiba ezithe tye.Yeyona ndlela ixhasayo esiyicebisayo.

Ufakelo lweChevron Wearstrips ULungiselelo

Ngelixa ufaka i-chevron arrangement wearstrips, nceda uhlawule ngokukodwa kubudlelwane obuchaseneyo phakathi kwe-angle ye-tangent ethe tye θ yee-wearstrips kunye nokuhlelwa kwe-pitch, i-P1.Nceda usebenze imitya yokunxiba ibe ngunxantathu oguquliweyo kwindawo yoqhagamshelwano yebhanti kunye neentambo zokunxiba;iya kwenza ibhanti lisebenze ngakumbi.

Itheyibhile yoLungiselelo lweChevron Wearstrip-P1

iyunithi: mm

| Iyalayisha | ≤ 30kg / M2 | 30 ~ 60kg / M2 | ≥ 60kg / M2 | ||||||||||

| DEG. | 30 ° | 35 ° | 40 ° | 45° | 30 ° | 35 ° | 40 ° | 45° | 30 ° | 35 ° | 40 ° | 45° | |

| Uthotho | 100 | 140 | 130 | 125 | 115 | 125 | 120 | 115 | 105 | 105 | 100 | 95 | 85 |

| 200A | 100 | 90 | 85 | 80 | 80 | 75 | 70 | 65 | 65 | 60 | 55 | 50 | |

| 200B | 90 | 80 | 75 | 70 | 70 | 65 | 60 | 55 | 55 | 50 | 45 | 40 | |

| 300 | 150 | 145 | 135 | 135 | 135 | 130 | 120 | 110 | 130 | 125 | 115 | 110 | |

| 400 | 90 | 80 | 75 | 70 | 70 | 65 | 60 | 55 | 55 | 50 | 45 | 40 | |

| 500 | 140 | 130 | 125 | 115 | 125 | 120 | 115 | 105 | 105 | 100 | 95 | 85 | |

Nceda ujonge kwitheyibhile engasentla malunga noluhlu lwepitch ukuze lungqinelane nobubanzi obuphakathi bomhambisi kwaye uhlengahlengise inowuthi ngokwakho.

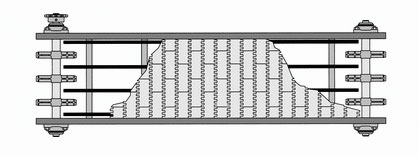

Isisombululo seNdawo yeSag

Ngelixa uthutha umthwalo onzima okanye usebenza kwiimeko ezingazinzanga, ezifana nokuqengqeleka kunye ne-sliding;i-sag yesakhiwo iya kubonakala kwindawo yokudibanisa ngenxa yengcinezelo yobunzima.Iya kubangela ukuba umphezulu webhanti wenze i-sag phakathi kwee-wearstrips kunye ne-drive/Idler sprocket.Iya kwenza ukubandakanyeka okungalunganga kwebhanti kunye nefuthe kwinkqubo yokuthutha.

Ukuze ugweme imeko ekhankanywe ngasentla, sincoma ukuba sithathe i-wearstrip yokuqinisa ukuqinisa inkxaso yebhande.

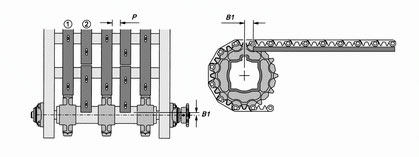

Owona Mgama ukufutshane ukusuka kwi-Wearstrip ukuya kwiziko le-Sprockets

Umlinganiselo ohambelanayo we-B1, nceda ubhekisele kwitheyibhile engezantsi.I-wearstrip ifakwe kwindawo yoku-1 kwaye i-B1 yafakwa kwindawo yesi-2. Ukuze ufumane i-pitch phakathi kokulungelelaniswa kwe-lateral cross, nceda ubhekisele kwi-Pitch.

Umzobo kwimenyu yasekhohlo.

| Uthotho | B1 |

| 100 | 26mm |

| 200 | 13mm |

| 300 | 23mm |

| 400 | 5mm |

IWearstrips Processing

Ii-Wearstrips zihlala zenziwe nge-TEFLON, okanye i-UHMW, i-HDPE imathiriyeli edibeneyo yeplastiki.Kukho ubungakanani obahlukeneyo obuqhelekileyo obunokuthengwa kwimarike.Ezi mpahla zokugqoka zinokudityaniswa kwintsimbi ye-angle ye-C ye-conveyor frame nge-welding, okanye ibotshelelwe ngezikrufu ngqo.Ngelixa ufakelo, nceda qinisekisa ukuba ugcine isithuba esaneleyo sokwandiswa kwe-thermal kunye nokucutheka kwemathiriyeli yeplastiki okubangelwa kukutshintsha kobushushu.Sincoma ubude bemathiriyeli yeplastiki ebigqunywe kwimitya yokunxiba ayinakho ukugqitha kwi-1500mm.

Xa iqondo lobushushu lendawo yokusebenza lingaphantsi kwama-37°C, nceda wamkele indlela A. Xa iqondo lobushushu lingaphezulu kwe-37°C, nceda wamkele indlela B. Ukuze usebenze ngcono nangokugudileyo, nceda ulungise izikhewu kuzo zombini iziphelo ze-wearstrip. unxantathu oguqulayo phambi kofakelo.

Iimpahla zokunxiba

Izinto ze-spacers ze-wearstrips yi-TEFLON, i-UHMW, kunye ne-HDPE ngokubanzi.Zisetyenzwa ukuze zilungele zonke iintlobo zeendawo zokusebenza.Nceda ujonge le theyibhile ingezantsi.

| Izinto eziphathekayo | UHMW / HDPE | Actel | |||

| Yomile | Imanzi | Yomile | Imanzi | ||

| Isantya esijikelezayo | < 40M / min | O | O | O | O |

| > 40M / min | △ | O | O | O | |

| Ubushushu obugciniwe | < 70 °C | O | O | O | O |

| > 70 °C | X | X | △ | O | |

Ubushushu obuphantsi

Kwimeko yokushisa ephantsi, iingubo zokugqoka zenziwe ngeplastiki, i-UHMW okanye i-HDPE, iya kuba yintlupheko ngenxa yokutshintsha komzimba, ukwandiswa kwe-thermal kunye nokunciphisa.Iya kuchaphazela ukusebenza kakuhle komhambisi.

Ngoko ke, ukuba uluhlu lwamaqondo obushushu ahlukeneyo phakathi kobushushu obuphezulu kunye nobushushu obuphantsi bungaphezulu kwe-25°C, kuyafuneka ukuba uthabathe i-wearstrip ene-chute yentsimbi ukuthintela ukwahlukaniswa kwe-spacer.

Ubushushu obuphezulu

Ibhanti lokuhambisa lemodyuli ye-HONGSEBLT ifanelekile ukuba isetyenziswe kuzo zonke iimeko ezingqongileyo zobushushu obuphezulu, obufana ne-95°C umphunga kunye ne-100°C yamanzi ashushu antywiliselwe njalo njalo. inkxaso kwimo engqongileyo enobushushu obuphezulu esichazile ngasentla.Kungenxa yokuba ziya kwanda kwaye zikhubazeke ngokunzulu kwindawo yobushushu obuphezulu;ibiya konakalisa umhambisi.

Kuphela ukuba isakhiwo esinoyilo olukhethekileyo, kunye ne-wearstrip inqunyelwe kwindlela eqhelekileyo emva kokubala kunye nokunciphisa ubungakanani bokwandiswa kunokunqoba intshutshiso ebangelwa kwindawo yokushisa ephezulu.Sinamava amaninzi okukunika inkcazo yobuchule kwireferensi.Nceda uqhagamshelane nesebe lobuchwephesha le-HONGSEBLT kunye nee-arhente zasekhaya ngolwazi oluthe vetshe.

Izinto zeplastiki ziya kuba thambileyo kwindawo enobushushu obuphezulu;ukulayishwa okugqithisileyo kunokunyusa ukukhuhlane kwaye kubangele umthwalo ogqithisileyo onokulimaza ibhanti kunye nemoto.Ngoko ke, kufuneka unciphise amandla ebhanti ukuya kwi-40% kunye neekhonkco zensimbi ezingenasici kwindawo yokusebenza apho izinga lokushisa lingaphezulu kwama-85 ° C.

Ngokwamava ethu ixesha elide, isantya sokuthutha siya kucotha kwindawo yobushushu obuphezulu.Sincoma ukuba wamkele iimveliso zensimbi engenasici kunye nomphezulu ogudileyo kwindawo emanzi okanye ephantsi kwamanzi, kwaye indawo yoqhagamshelwano ayikwazi ukuba ngaphezu kwe-20mm.Unokwenza kwakhona insimbi engenasici ngenkqubo ye-TEFLON yomhlaba, ilungile ekunciphiseni i-friction factor.