Umhambisi weSwanneck

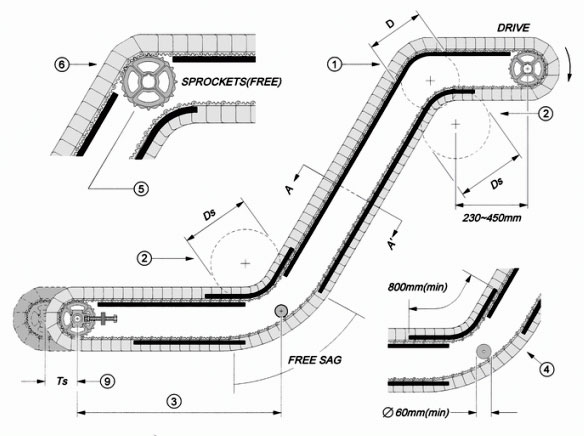

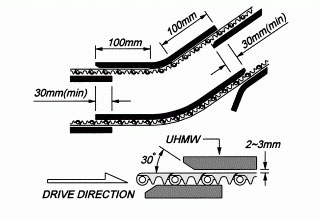

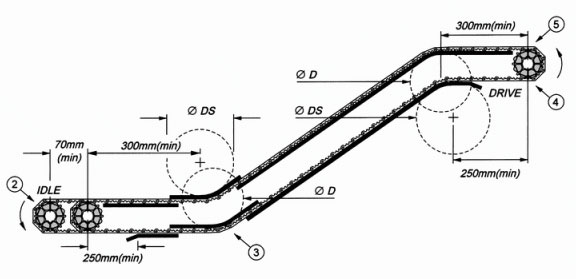

Indlela yokuxhasa indawo egobileyo ye-conveyor incline iyakwazi ukusebenzisa imichilo yeplastiki ene-friction ephantsi, njenge-UHMW, HDPE, kunye ne-Acetal, ukuba ibe yinkxaso ephantsi.Ngobuncinane bedayamitha egobileyo, nceda ubhekisele kwiinkcukacha zeXabiso le-D&Ds.

I-backbend radius yi-tension eqinile;Nceda wamkele imicu yeplastiki enokukhuhlana okusezantsi, njenge-UHMW, HDPE, kunye ne-Acetal ukuyivelisa.Ngobuncinane bedayamitha egobileyo, nceda ubhekisele kwiinkcukacha zeXabiso le-D&Ds.

Isikhundla sokuqhuba kwindlela yokubuyisela ye-swanneck ethambekele yokuhambisa kwakhona luhlobo lweradiyasi ye-backbend;kukuxinezeleka okuxekethileyo.Inokuthi iyilwe ngeerola okanye imicu yeplastiki ene-friction esezantsi yokuxhasa.

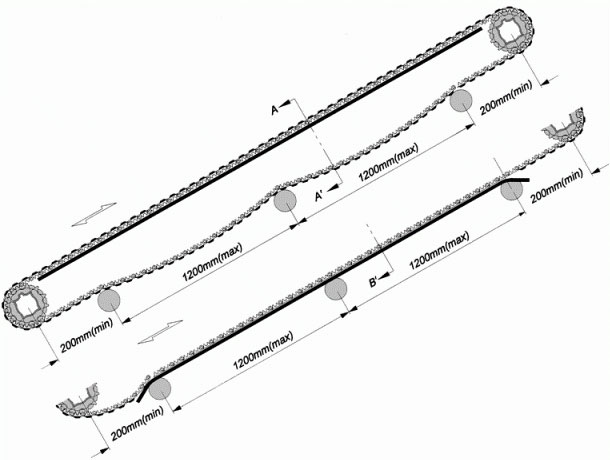

Ukuba ubude obuthe tye phakathi kwe-sprocket engasebenziyo kunye nendawo egobileyo ingaphezulu kwe-900mm, nceda ufake i-wearstrip emazantsi endlela yokubuya.

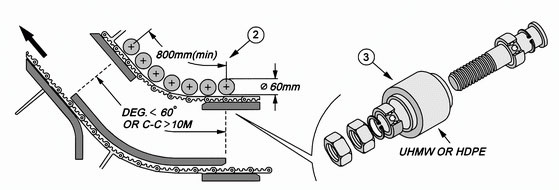

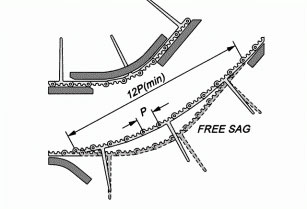

Xa kukho i-catenary sag ebonakala kwi-returnway ye-swanneck yokuhambisa i-conveyor kunye nesantya sokusebenza asidluli 20M / min, sinokungahoywa kwaye sivumele ukuba sag ngokukhululekile.Nangona kunjalo, ukuba isantya sidlula i-20M / min, kuyimfuneko ukuseta i-roller enobubanzi obungaphezulu kwe-60mm ukunciphisa isiganeko sokutsiba esibangelwa yi-catenary sag yebhanti yokuhambisa.

Xa wamkela i-Hongsbelt drive sprocket ukuba ibe yindlela exhasayo ye-angle egobileyo kunye nesantya sokusebenza sidlula i-15m / min, kufuneka isetyenziswe i-sprocket enamazinyo angaphezu kwe-12, kodwa nceda ulungise zonke ii-sprockets kunye nokugcina amakhonkco kwaye ususe ipleyiti ekhokelayo ukusuka. i-sprocket.

Kuyimfuneko ukuyila ngeerola ezicinezelweyo okanye imichilo kwi-swanneck ethambekele kwi-conveyor.I-pitch enxuseneyo yemigca ayinako ukuba ngaphantsi kwe-100mm kwaye kufuneka imisele isilungelelanisi soxinzelelo kwindawo yokungenzi nto ukufumana uxinezeleko olufanelekileyo.

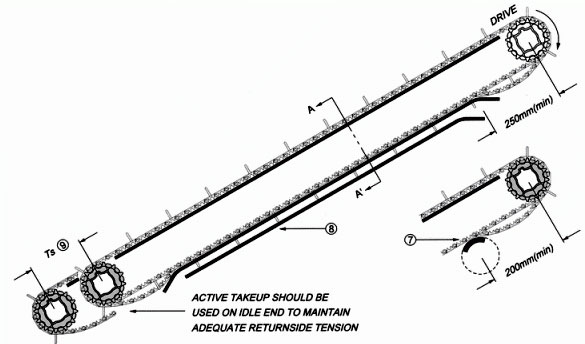

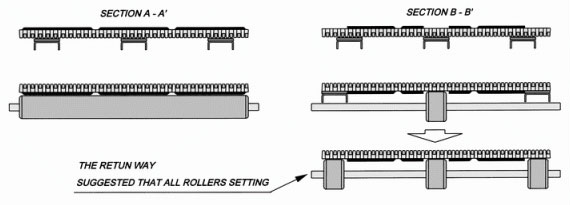

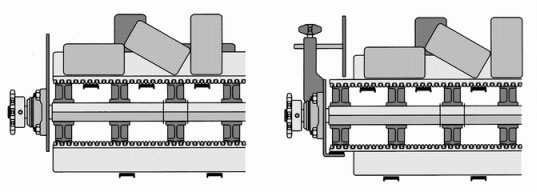

Icandelo A-A' Inkcazo yoyilo

IConveyor

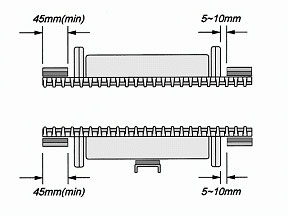

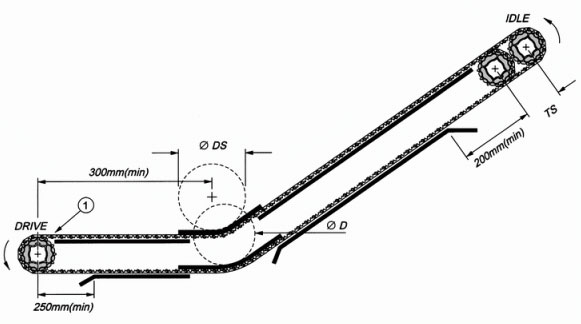

Ukuba indlela yokuqhuba ye-conveyor ethambekele kwi-drive iphezulu, indawo yoqhagamshelwano phakathi kweziko le-sprocket ye-drive kunye ne-roller yokuqala okanye i-wearstrip kwindlela yokubuyisela kufuneka igcine ikhefu elingaphezu kwe-200mm ukuvumela ibhanti libe nesithuba esaneleyo sokuhamba kwaye ugweme ukuba nokuzibandakanya okungaqhelekanga kunye ne-sprockets. kwaye kukhokelela kwimeko exineneyo.Nceda ujonge indawo yesi-7 kulo mfanekiso ungentla.

Ukuba ububanzi bebhanti bungaphezulu kwe-600mm, kufuneka kufakelwe imitya encedisayo eseziko kumphezulu wenqwelomoya ngendlela ebuyayo.Nceda ujonge kwiCandelo A-A' kwaye ubone indawo yesi-8 kulo mfanekiso ungentla.

I-TS luhlengahlengiso loxinzelelo;kummiselo wokulungelelanisa izithuba, nceda ubhekisele kwisahluko soBubude bebhanti kunye noxinzelelo.Nceda ujonge indawo yesi-9 kulo mfanekiso ungentla.

Icandelo A-A' Inkcazo yoyilo

Chwetheza i-EL

Isithuba phakathi kwe-drive/idler sprocket kunye nendawo yokuqala yoqhagamshelwano ngendlela yokubuyisela, kungakhathaliseki ukuba yintoni i-roller okanye i-wearstrip, kufuneka igcinwe ngaphezu kwe-200mm.

Umgama ophezulu phakathi kwazo zonke ii-roller ezixhasayo kwindlela yokubuyisela ayikho ngaphezu kwe-1.2M.

Ukufumana amanye amanqaku oyilo, nceda ubhekisele kwi-Swanneck Conveyor kunye nomfanekiso ongezantsi.

Kwi-Series 200 EL kunye ne-Series 300HDEL, zacutshungulwa kwaye zancamathelwa iziqwenga ze-TPE kwibhanti yezinto zePP.I-TPE yimathiriyeli yenqanaba eliphezulu le-skidproof;esona sicelo sixhaphakileyo sisiphatho se-skidproof yeebrashi zamazinyo.Inokuphinda isetyenziswe ngaphandle kokuthandabuza malunga nokhuseleko lokusingqongileyo, kwaye idityaniswe nezinto zePP ukuze ibe sisongezo esinokomeleza ukuqina.Kungakhathaliseki ukuba iyancipha okanye iyancipha, i-angle of inclination ayikwazi ukudlula i-40 °.

INkcazelo yoYilo lweCandelo

Ubuncinci be-diameter ye-roller yendlela yokubuya ayikwazi ukuba ngaphantsi kwe-600mm.Inokusebenzisa iirola ngendlela yokubuyisela kuhambo lonke;kunjalo, isantya kufuneka ibe ngaphakathi 30M/min kunye sag catenary kufuneka ilawulwe ngaphakathi 35mm ukuphepha TPE flange ebetha rollers nge engile enkulu kwaye kubangele ukusebenza kakubi.

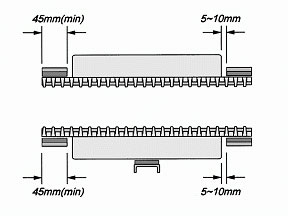

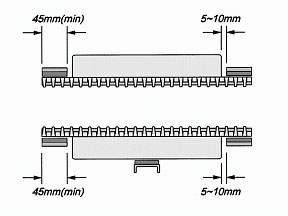

Isenokwamkela indlela yoyilo njengoko kubonisiwe, icandelo B-B', libonisa apha ngasentla.Kulo mzekeliso ungentla, ii-wearstrips zixhaswa kumacala omabini kunye ne-roller exhaswa embindini.Kumzekeliso ongezantsi, yamkela iirola ukuxhasa kumacandelo amathathu.Zombini zezona ndlela ilungileyo yoyilo.

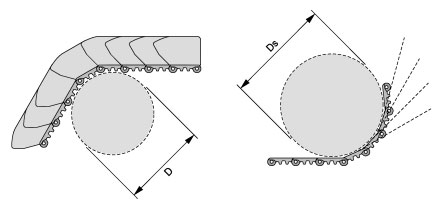

Umqolo weRadius DS

Zonke iibhanti zokuhambisa ze-HONGSBELT zeemveliso ze-serial zadityaniswa kwiyunithi edibeneyo, inomlinganiselo omncinci wokubuyisela umva werediyasi;Ngoko ke, ukwenza ibhanti lidlule kwindawo engasemva ngokutyibilikayo, nceda unikele ingqalelo kumda wobuncinane bedayamitha xa uyila umthumeli kwaye ubhekisele kwitheyibhile engezantsi yokulungisa iradiyasi yochungechunge ngalunye).

Ibhanti lokuhambisa le-HONGSBELT liyakwazi ukusebenza kuyilo oluthambekileyo lokuhambisa;ngokusisiseko iyafumaneka ukufikelela nakweyiphi na i-engile ethambekileyo ngezibalo ezichanekileyo zeradiyasi ye-backbend.

iyunithi: mm

| Uthotho | 100 A | 100 B | 200 A | Ngowama-200 B | 300 | 400 | 500 | 501B | 502A/B | |

| D | Ngaphandle koMlindi osecaleni | 250 | 250 | 135 | 120 | 200 | 45 | 150 | 150 | 180 |

| Kunye noMlindi osecaleni | 250 | 250 | 135 | 120 | 200 | -- | -- | 180 | 200 | |

| DS | Ngaphandle koMlindi osecaleni | 250 | 200 | 150 | 120 | 220 | 45 | 150 | 180 | 200 |

| Kunye noMlindi osecaleni | 280 | 230 | 300 | 290 | -- | -- | -- | 200 | 230 | |

Backend Radius Bamba Phantsi Ingcaciso

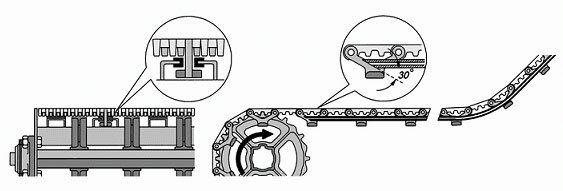

Iradiyasi yangasemva yenkqubo yokuhambisa etyekelelweyo luyilo oluxhaphake kakhulu lokuphumeza injongo yokuhambisa ethambekele.Ngoko ke, kuyimfuneko ukuthatha intshukumo egudileyo yobuso bebhanti okanye ezantsi kwi-akhawunti xa uyila indawo yokubamba.Nceda ujonge lo mfanekiso ungasentla.Ngokuphathelele kwizinto ezifanelekileyo zokunxibelelana kunye nokugqoka ibhanti, sincoma ukuba sithathe i-HDPE okanye i-UHNW impahla xa isantya singaphantsi kwe-20 M / min;ukuba isantya singaphezulu kwe-20 M / min, nceda wamkele izinto ze-UHMW okanye ze-TEFLON.

Nceda usebenze okanye ucole indawo yokubamba ukuya kuma-30 degree chamfer ekungeneni ukuze uqinisekise umthumeli ngentshukumo egudileyo.

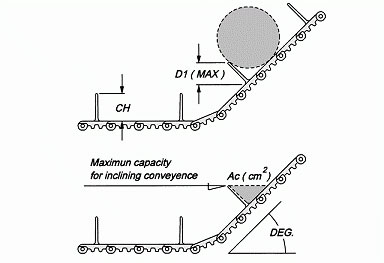

Iengile kunye nesakhono

Ukuba umthamo wokuthutha iimpahla ukhulu kakhulu, ukwenzela ukuphepha amanqaku awela kwinkqubo yokuthutha, akufanelekanga ukwamkela abalindi becala eliphantsi okanye ukuyila kunye ne-gradient enqabileyo kwi-conveyor ethambekele.Nceda unike ingqwalasela eyodwa kubudlelwane obunxulumene phakathi komthamo wempahla kunye ne-angle yokuthomalalisa, kwaye ubhekisele kumfanekiso ongezantsi.

Iyunithi : CH=mm, D1= mm, Ac=cm2

| DEG. | 15 ° | 20 ° | 25 ° | 30 ° | 35 ° | 40 ° | 45° | 50 ° | ||

| CH | 25 | D1 | 23 | 22 | 21 | 20 | 19 | 17 | 16 | 15 |

| Ac | 11 | 8 | 6 | 5 | 4 | 3 | 3 | 2 | ||

| 50 | D1 | 46 | 45 | 46 | 40 | 38 | 35 | 32 | 29 | |

| Ac | 46 | 34 | 26 | 21 | 17 | 14 | 12 | 10 | ||

| 75 | D1 | 70 | 67 | 64 | 61 | 57 | 53 | 48 | 42 | |

| Ac | 104 | 77 | 60 | 48 | 40 | 33 | 27 | 23 | ||

| 100 | D1 | 9. | 90 | 86 | 81 | 76 | 70 | 64 | 57 | |

| Ac | 186 | 137 | 107 | 86 | 71 | 60 | 50 | 41 | ||

| 125 | D1 | 117 | 113 | 108 | 102 | 95 | 88 | 80 | 71 | |

| Ac | 291 | 214 | 167 | 136 | 111 | 92 | 77 | 65 | ||

| 150 | D1 | 140 | 136 | 129 | 122 | 114 | 106 | 96 | 86 | |

| Ac | 490 | 360 | 281 | 227 | 186 | 156 | 130 | 109 | ||

Ngesiphumo sokulayisha umthamo, nceda uphindaphinde ixabiso le-Ac ngobubanzi obusebenzayo (cm) bendiza .

Yala iConveyor

Ngokubanzi, kuyilo lwenkqubo yokuhambisa yokwehla, sincoma ukusebenzisa uhlobo A okanye uhlobo B njengomzekelo wokuhambisa.inkqubo yothutho yenzelwe ukuqhuba ezantsi kwiconveyor njengoko indawo yoku-1 yomfanekiso ongezantsi ibonisa.Ngexabiso le-D & DS, nceda ubhekisele kwi-Backend Radius Ds kwimenyu esekhohlo.

Uhlobo B

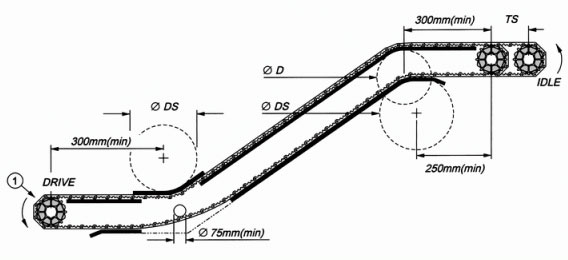

Ukuba kuyimfuneko ukwamkela uhlobo C njengomzekelo wokuyila umthumeli, i-spacing yokulungelelanisa iT kufuneka igcinwe ubuncinane i-75mm.Ngexabiso le-D & DS, nceda ubhekisele kwi-Backend Radius Ds kwimenyu esekhohlo.

Uhlobo C

Uxinzelelo olufanelekileyo lwendawo yesi-3 kufuneka ifumane kwi-tension adjustment of position 2.

Ukuze wenze i-radius ye-backend kwindawo yesi-4 kunye nezantsi kwe-sprocket ye-drive ukuze ufumane i-angle ehambelanayo efanelekileyo kunye noxinzelelo olufanelekileyo, kwaye uzuze ukusebenza kwebhanti, kuyimfuneko ukulungelelanisa uxinzelelo kwindawo yesi-2 kwaye ubambe phantsi kwindawo yesi-3.

Ukuba ayikwazi ukufumana uxinezeleko olululo ngesikhundla sesi-2, oko kuya kubangela ukuba i-engile yokugoba ingafunyanwanga ukusuka kwindawo yesi-3 neyesi-4. I-sprocket iya kuba nothethathethwano olungalunganga kwaye ibangele ukunqumama kunye nokusilela.

Uhlobo D

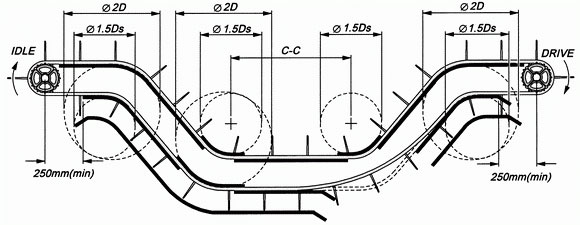

Multi Backend Radius

Kuyilo lweradiyasi ye-backend emininzi, iintambo zokunxiba kufuneka zibekwe kwindlela ebuyayo ukuxhasa umphezulu wokubhabha, ukuze kuthintelwe ukonakala kwebhanti okanye ukudilika kwesakhelo sokuhambisa.Nceda ujonge lo mfanekiso ungezantsi.

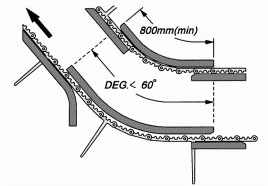

Ukuba i-engile yokugoba ingaphantsi kwe-60 degree, inokusebenzisa isiporo sokubambelela esenziwe ngeplastiki yobunjineli ye-UHMW ukubamba icala omabini ecala lebhanti elisecaleni.Ukufumana ireferensi yexabiso leD & DS nceda ubone le theyibhile ilandelayo ekupheleni kweli phepha ngezantsi.)

Ukuba i-angle yokuthomalalisa ingaphezulu kwe-60 degree, sincoma ukusebenzisa i-roller eqhutywayo kwindawo yokubeka phantsi kwebhanti, njengokunciphisa indawo ye-abrasion kunye nokunciphisa i-tension yendlela yokubuya.

Isimbo sokuthwala ukubamba phantsi irola kufuneka yakhiwe ngolungiso oluchanekileyo, kufuneka iqiniswe ingaguquki kwi-engile yentsimbi yefreyimu yokuhambisa ngescrew exhasayo njengoko kubonisiwe ngasentla.(Ukwenzela ireferensi yexabiso leD & DS nceda ujonge le theyibhile ilandelayo ekupheleni kweli phepha ngezantsi.)

Umgama wendlela yokubuya ucetywayo ucetyiswe ukuba kugcinwe ubuncinane iimodyuli ezili-12 ububanzi, ukuze kwenziwe indlela yokubuya ibe nesithuba esaneleyo sokukhulula uxinzelelo.

Amanqaku

I-HONGSBELT ibhanti yemodyuli ifaneleke kakhulu ukuba isetyenziswe kuzo zonke iintlobo zeendawo eziphakamileyo zokushisa, ezifana ne-steam kunye namanzi ashushu afakwe emanzini njl.n iradiyasi yangasemva.Sinamava amaninzi kwisicelo sobushushu obuphezulu, kwaye sizimisele ukukusebenzela.Kumanqaku anxulumeneyo oyile inkqubo yokuhambisa, ungathethathethana nathi ngalo lonke ixesha.

Bamba Phantsi Iimodyuli

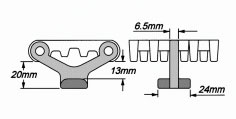

I-Incline conveyor inokunqumamisa ukubamba iimodyuli (i-HDM), sisixhobo esikhokelayo esilungiselelwe ngokukodwa i-radius ye-backend kwindlela yokubuya yokuhambisa.Iimodyuli zokubamba zikwi-design eyi-T, kwaye zifakwe kwi-underside yebhanti, ukubamba ibhanti.Inokufikelela kwisiphumo sokuthambeka ngaphandle kokubamba indawo yeradiyasi yangasemva, kwaye ungamkeli iirola ukuxhasa ibhanti kwindlela yokubuya.

Inkcazo yoFakelo lweHDM

Xa ufaka i-HDM, nceda wamkele i-coefficient ephantsi ye-friction coefficient materials njenge-UHMW okanye i-HDPE kwindawo yoqhagamshelwano.Musa ukuvumela ukudibana kwe-HDM kunye nezinto zentsimbi ngokuthe ngqo.Inokonakalisa ibhanti lokuhambisa ngenxa yokukhuhlana.Ukucwangcisa, Ukusetyenzwa komtya wokunxiba kumnyango we-30 degree chamfer ukufumana ukusebenza okungcono kwe-HDM.Nceda ujonge kumfanekiso ongentla.

Uthintelo olusecaleni

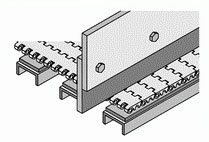

I-HONGSBELT ibhanti yokuhambisa imodyuli inokuncamathela kunye nohlobo olusisigxina lwabagadi becala ukukhusela iimveliso ziwe ukusuka kumda webhanti.Imathiriyeli yeplastiki yobunjineli yoxinaniso oluphezulu kufuneka isetyenziswe kulwakhiwo lokuncamatheliswa koonogada abasecaleni, kwaye kufuneka igcine isithuba sokhuseleko phakathi kwebhanti kunye nohlobo olusisigxina lomlindi wecala.Ngaphezu koko, kuyafuneka ukunqanda ukusebenzisa izinto ezithambileyo ezifana ne-PVC, i-PU okanye imathiriyeli yokuluka ifayibha ukuhlikihla kumphezulu webhanti ngokuthe ngqo, inokubangela umonakalo kumphezulu webhanti.Nceda ujonge kumfanekiso ongezantsi.

IMveliso Enkulu Nengangcolisekiyo

Usetyenziso olungentla alukho ungcoliseko okanye ukuhanjiswa kweemveliso ezinkulu.Lo mzekelo woyilo wandiswa isakhiwo esiphambili somthumeli ngokuthe ngqo, ukwenza umsebenzi njengabalindi becala.

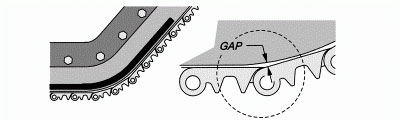

Amanqaku oMsantsa wokugoba ibhanti

Ubume beemveliso ze-HONGSBELT yiyunithi edibeneyo edibeneyo.Ngoko ke, kungakhathaliseki ukuba uthintelo lwecala luqinile kangakanani, i-gap ye-triangular iya kubonakala kwindawo yokugoba yebhanti.Nceda ujonge kumfanekiso ongentla.Kufuneka kuthathelwe ingqalelo ngexesha lokuyila okanye kuqwalaselwe ukwamkela izincedisi ze-HONGSBELT, abalindi abasecaleni.Ukongeza, into efana ne-HDPE okanye i-UHMW warp, ingxowa yeplastiki enomphetho, intsalela yempahla yeplastiki okanye enye into ecaba kunye nencinci inokuthi ingene kwisithuba sebhanti okanye i-slot.

Ezi zinto zangaphandle zinokubangela ukuba umthumeli kwiimeko zokuxinana okanye ukuphazamisa ukujikeleza kwebhanti, ukuba akukho nkathalo ukuncamathela kunye ne-HONGSBELT unogada wecala lokuthintela ukuwa kwecala, sicebisa ukuba ubuncinci obuncinci bempahla yokuhambisa kufuneka ubuncinane ubukhulu obuphindwe kabini obukhulu kune-gap yebhanti engunxantathu.

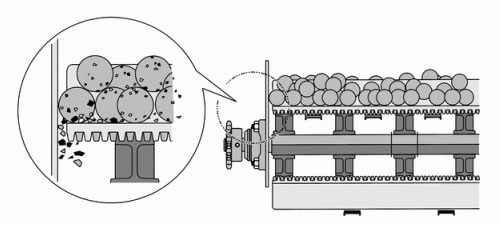

Amacandelo amancinci

Izinto ezincinci kunye nezinto ezingcoliseka ngokulula ezifana neebhiskithi, iziqhamo ezomileyo, kunye nefula kulula kakhulu ukuwa ukusuka kumphezulu webhanti.Iincinci ezincinci zezi zixhobo ziya kuxutywa kwisakhiwo sokuhambisa, kwaye zehle kwi-chink yebhanti yokuhambisa.Ukuthintela ukuba into encinci ingene kwibhanti kunye nesakhiwo sokuhambisa, sincoma ukuba uyile umthumeli wakho njengoko ubonisa ngezantsi;iya kufumana ukhuseleko olungcono kwisixhobo.